Our Threading Offer

Dormer Pramet's threading tools offer exceptional process security in what is one of the most critical and problematic machining processes. Our tools for threading cater for a variety of chamfer lengths and thread forms. This includes dies and die-nuts, general purpose hand and machine taps, multi-material and material-specific taps, fluteless taps and thread milling cutters. We also provide indexable tools for internal threading and external threading. This includes both full and partial profile inserts with a wide range of tool holders and threading bars.

Our broad range of taps and dies covers all common threadforms, supporting use by hand or machine in straight flute, spiral point and spiral flute designs. This includes taps designed for multi-material thread production as well as our Shark Line taps with optimised geometries for high-performance threading of specific workpiece materials. We also offer fluteless taps for extremely secure, chip-free threading in malleable materials.

Dormer’s material-specific DIN taps, known as SHARK LINE, are renowned for their high performance and are easy to recognise thanks to the colour rings indicating the material type(s) for which they are designed.

Solid carbide taps provide the highest rates of productivity in hard and abrasive materials up to 63 HRC. Their highly stable design means low risk of tap breakage and optimum process security. They are available in a variety of styles including straight flute, spiral flute and fluteless, with internal coolant options for optimum chip evacuation when threading short-chipping materials.

As with the drills, Dormer Pramet also has a number of different variants of threading sets. The smaller ones also come with suitable drills, making life easier for machinists and skilled workers – you always have all the tools you need to hand. The more extensive sets also include tap wrenches and dies with associated die stocks.

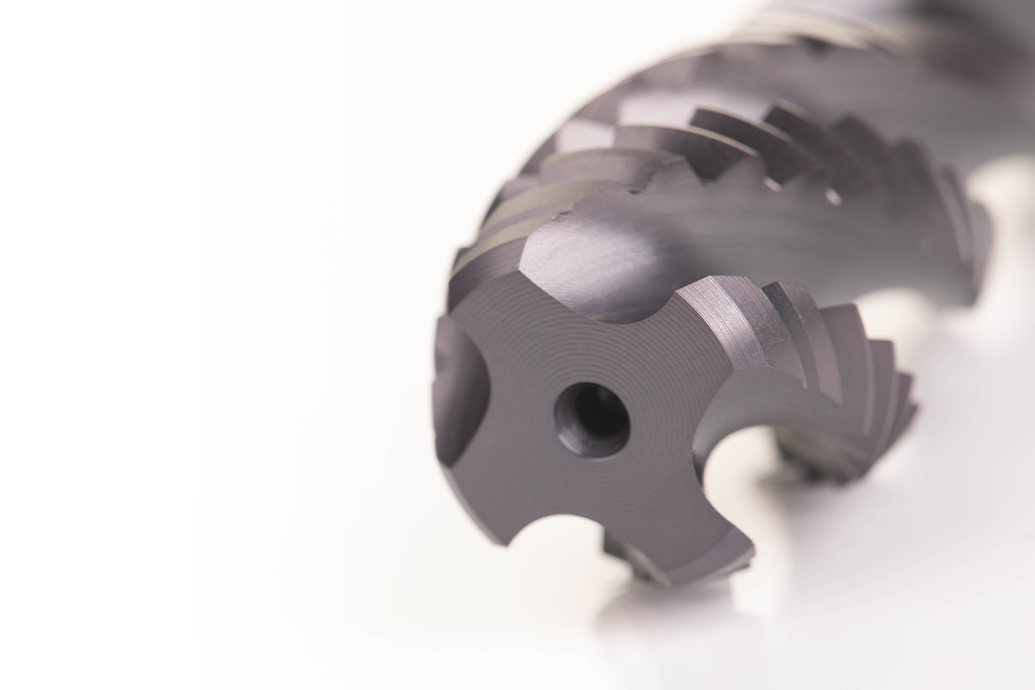

Thread milling supports highly accurate, larger diameter thread creation on CNC machines. Our program of Thread Milling cutters covers M, MF, UNC, UNF, G & NPT thread forms. All provide a high level of security, stability and surface finish. Extremely versatile, the same cutter can be used in almost all workpiece materials including hardened steels, stainless steels and difficult-to-machine alloys.