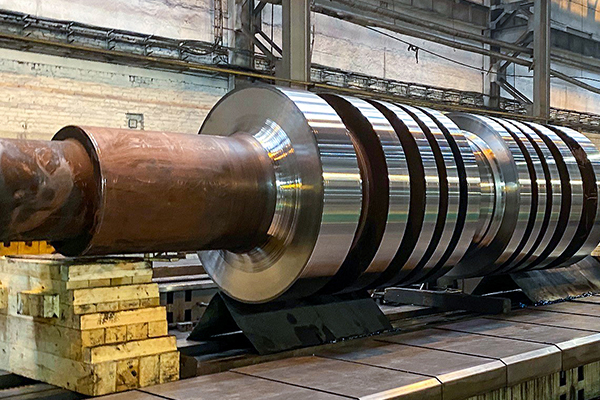

Heavy machining

Our assortment of cutting tools for heavy machining applications includes both milling and turning products. Here, we focus on removing the first layer of material from large-scale forgings, castings and rollings.

Typical customers are major, high-volume manufacturers, material suppliers and sub-contractors providing pre-machined blanks. These operations require highly reliable tools capable of working in very tough conditions.

Our significant experience means we have a broad customer base, with Dormer Pramet tools machining crank shafts on cruise liners to components for the largest wind power generators!

We offer dedicated geometries for chip control, grades that provide reliable tool life and longevity, with a rapid response for tailor-made tooling.

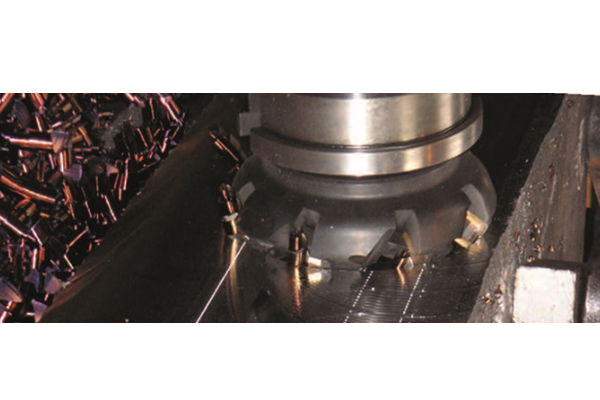

Heavy Milling

Our milling range includes face milling cutters, 90° shoulder milling cutters, helical milling cutters, chamfer milling cutters and special milling cutters. Our main priorities in this application are high metal removal rates and reliability of the cutting edge.

Heavy Turning

For heavy turning we offer a selection of positive and negative insert geometries and corresponding tool holders designed for removing the first uneven layer of material. Eccentricity of the workpiece is very common, and our tools are manufactured to provide mechanical stability. Indexable inserts need to cope with very abrasive workpiece surfaces and be both wear resistant and tough to withstand the interrupted cut. These products can achieve high metal removal rates up to 1500kg/hour.

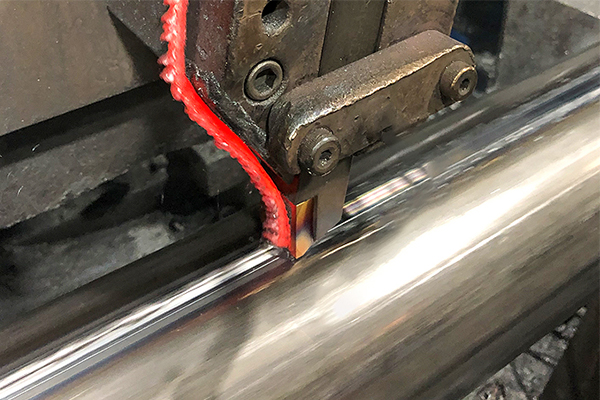

Bar peeling

We offer a specific assortment for bar diameter reduction and removal of metallurgical defects from forged and rolled blanks. This includes inserts in different shapes, geometries and grades for steels, stainless steels, and other difficult-to-machine materials. In addition, we provide clamping systems and cassettes to meet a variety of customer needs, such as process reliability, surface quality and durability of the cutting edge. Important elements within this application are high productivity, dimensional accuracy, and excellent surface quality.

Tube machining applications

In addition, we supply a comprehensive set of solutions for various operations performed in the tube manufacturing industry, including:

Scarfing

Through our long-term focus in this field, we are one of only a handful of global companies to offer a complete program of inserts for scarfing - the process of removing the weld deposit created during tube production. Our assortment covers external scarfing inserts and tool holders, as well as rings for internal operations in all common tube diameters.

Tools for processing tubes and pipes with large diameters:

We produce a wide assortment of special products for producers of large diameter tubes.

This includes tools used for strip chamfer milling operations in preparation for the longitudinal welding process, as well as products for the final bevelling operation of the tube face surface, with angles according to customer needs.

Also, within this portfolio are custom-made products for special thread profiles, according to API and GOST specification, for both internal and external tube and coupling threads.

Tool holders and indexable inserts are optimized to meet the high accuracy expectation desired for these types of products and applications.