Bright and TiN (Tip Coating)

A0223.0

022 Stub Drill

Material ID: 5967079

Stub length drill with straight shank, diameter 3mm with an overall length of 46mm and flute length of 16mm according to DIN/ANSI standard with 135° split point, HSS with TiN-tip coating for 2.5xD drilling without pecking in steel and cast iron

Product Feature

High Speed Steel Tool Material

DIN/ANSI Standards

2.5×D Usable Tool Depth to Diameter Ratio

Drill Point 135°

Cylindrical Shank / Straight Shank

Standard Spiral Flute Design

Right Hand Rotation / Cutting

h8 – Industry Standard Tool Tolerance Zone (based on diameter range)

Product Detail

Description | Value |

|---|---|

| EAN number | 7320760588697 |

| Product number (SAP) | 86008223 |

| Ordering code ANSI | A0223.0 |

| Gross weight - grams | 2.6 |

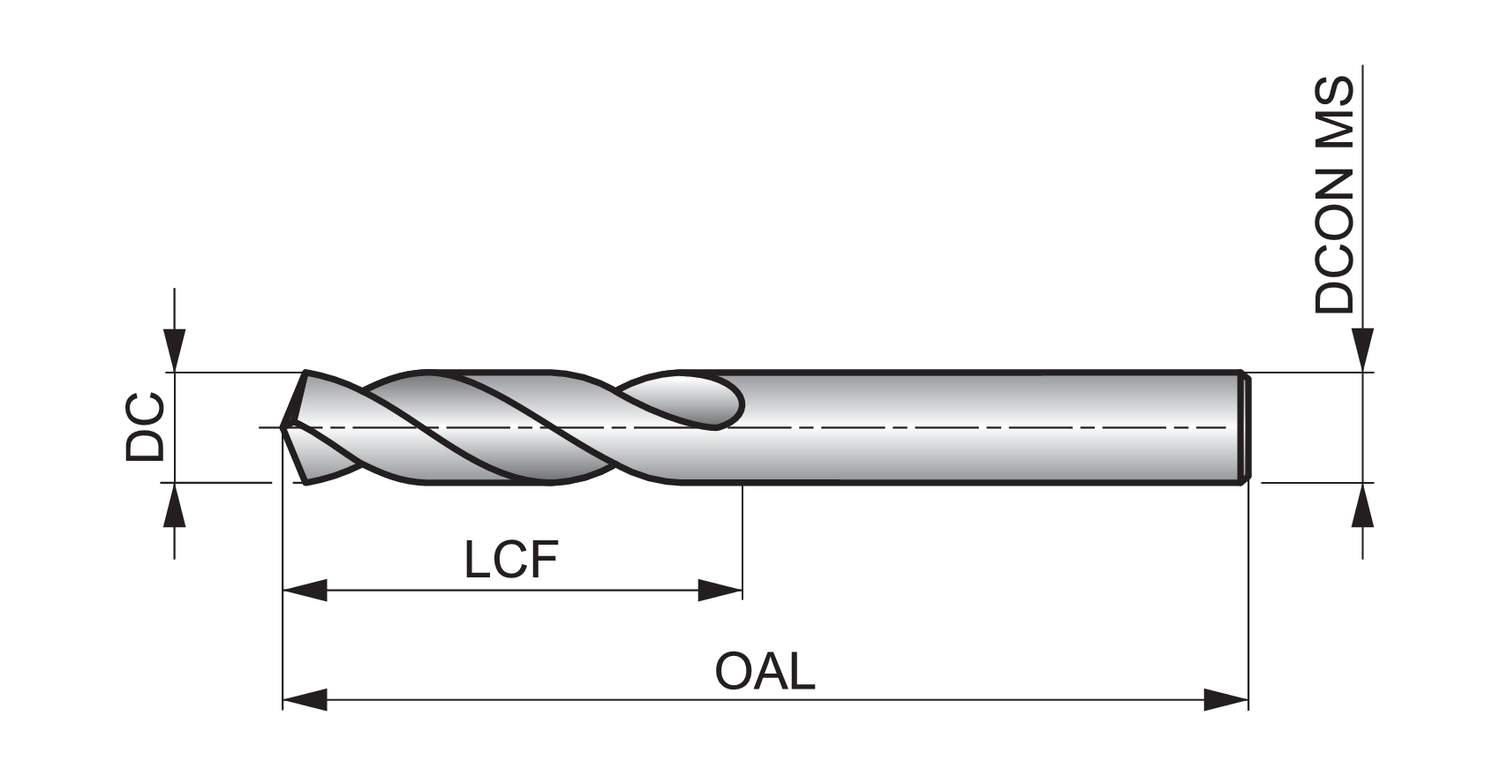

| Cutting diameter - millimeter (DC) | 3 mm |

| Cutting diameter - inch (DC) | 0.1181 inch |

| Length chip flute - millimeter (LCF) | 16 mm |

| Overall length - millimeter (OAL) | 46 mm |

| Connection diameter - millimeter (DCON MS) | 3 mm |

| Length chip flute - inch (LCF) | 0.6299 inch |

| ISO | A0223.0 |

Cutting Conditions

| Suitability | vc | f | |

|---|---|---|---|

| P1.1 - Free machining sulfurized carbon steel with a hardness of < 240HB | Primary use | 33 m/min | 0.15 mm/rev |

| P1.2 - Free machining sulfurized and phosphorized carbon steel with a hardness of < 180HB | Primary use | 37 m/min | 0.15 mm/rev |

| P1.3 - Free machining sulfurized/phosphorized and leaded carbon steel with a hardness of < 180HB | Primary use | 38 m/min | 0.15 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| P2.1 - Plain low carbon steel containing < 0.25%C with a hardness of < 180HB | Primary use | 28 m/min | 0.15 mm/rev |

| P2.2 - Plain medium carbon steel containing < 0.55%C with a hardness of < 240HB | Primary use | 25 m/min | 0.119 mm/rev |

| P2.3 - Plain high carbon steel containing > 0.55%C, with a hardness of < 300HB | Primary use | 22 m/min | 0.084 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| P3.1 - Alloy steel with a hardness of < 180HB | Primary use | 24 m/min | 0.102 mm/rev |

| P3.2 - Alloy steel with a hardness of 180 - 260HB | Primary use | 19 m/min | 0.102 mm/rev |

| P3.3 - Alloy steel with a hardness of 260 - 360HB | Primary use | 16 m/min | 0.084 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| P4.1 - Tool steel with a hardness of < 26HRC | Primary use | 14 m/min | 0.102 mm/rev |

| P4.2 - Tool steel with a hardness of 26 - 39RC | Primary use | 12 m/min | 0.084 mm/rev |

| P4.3 - Tool steel with a hardness of 39 - 45HRC | Possible use | 10 m/min | 0.062 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M1.1 - Stainless steel, ferritic with a hardness of < 160HB | Primary use | 21 m/min | 0.084 mm/rev |

| M1.2 - Stainless steel, ferritic with a hardness of 160 - 220HB | Primary use | 17 m/min | 0.084 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M2.1 - Stainless steel, martensitic with a hardness of < 200HB | Primary use | 18 m/min | 0.084 mm/rev |

| M2.2 - Stainless steel, martensitic with a hardness of 200 - 280HB | Primary use | 15 m/min | 0.084 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M3.1 - Stainless steel, austenitic with a hardness of < 200HB | Possible use | 9 m/min | 0.119 mm/rev |

| M3.2 - Stainless steel, austenitic with a hardness of 200 - 260HB | Possible use | 8 m/min | 0.119 mm/rev |

| M3.3 - Stainless steel, austenitic with a hardness of 260 - 300HB | Possible use | 7 m/min | 0.119 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M4.1 - Stainless steel, austenitic-ferritic or super-austenitic with a hardness of < 300HB | Possible use | 9 m/min | 0.062 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K1.1 - Gray iron, ferritic or ferritic-pearlitic with a hardness of < 180HB | Primary use | 32 m/min | 0.15 mm/rev |

| K1.2 - Gray iron, ferritic-pearlitic or pearlitic with a hardness of 180 - 240HB | Primary use | 24 m/min | 0.119 mm/rev |

| K1.3 - Gray iron, pearlitic with a hardness of 240 - 280HB | Primary use | 18 m/min | 0.119 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K2.1 - Malleable iron, ferritic with a hardness of < 160HB | Primary use | 25 m/min | 0.084 mm/rev |

| K2.2 - Malleable iron, ferritic or pearlitic with a hardness of 160 - 200HB | Primary use | 20 m/min | 0.084 mm/rev |

| K2.3 - Malleable iron, pearlitic with a hardness of 200 - 240HB | Possible use | 16 m/min | 0.084 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K3.1 - Ductile (nodular/spheriodal) iron, ferritic with a hardness of < 180HB | Primary use | 22 m/min | 0.084 mm/rev |

| K3.2 - Ductile (nodular/spheriodal) iron, ferritic or pearlitic with a hardness of 180 - 220HB | Primary use | 17 m/min | 0.084 mm/rev |

| K3.3 - Ductile (nodular/spheriodal) iron, pearlitic with a hardness of 220 - 260HB | Possible use | 13 m/min | 0.084 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K4.1 - Austenitic cast iron with a hardness of < 180HB | Primary use | 20 m/min | 0.084 mm/rev |

| K4.2 - Austenitic cast iron with a hardness of 180 - 240HB | Primary use | 15 m/min | 0.084 mm/rev |

| K4.3 - Austempered ductile iron with a hardness of 240 - 280HB | Possible use | 11 m/min | 0.084 mm/rev |

| K4.4 - Austempered ductile iron with a hardness of 280 - 320HB | Possible use | 10 m/min | 0.084 mm/rev |

| K4.5 - Austempered ductile iron with a hardness of 320 - 360HB | Possible use | 8 m/min | 0.084 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K5.1 - Vermicular, compacted graphite iron with a hardness of < 180HB | Primary use | 23 m/min | 0.084 mm/rev |

| K5.2 - Vermicular, compacted graphite iron with a hardness of 180 - 220HB | Primary use | 17 m/min | 0.084 mm/rev |

| K5.3 - Vermicular, compacted graphite iron with a hardness of 220 - 260HB | Possible use | 13 m/min | 0.084 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| N1.1 - Pure aluminium and wrought aluminium alloys with a hardness of < 60HB | Primary use | 40 m/min | 0.073 mm/rev |

| N1.2 - Wrought aluminium alloys with a hardness of 60 - 100HB | Primary use | 30 m/min | 0.073 mm/rev |

| N1.3 - Wrought aluminium alloys with a hardness of 100 - 150HB | Primary use | 20 m/min | 0.15 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| N2.1 - Cast aluminium alloys with a hardness of < 75HB | Primary use | 49 m/min | 0.135 mm/rev |

| N2.2 - Cast aluminium alloys with a hardness of 75 - 90HB | Primary use | 44 m/min | 0.135 mm/rev |

| N2.3 - Cast aluminium alloys with a hardness of 90 < 140HB | Primary use | 32 m/min | 0.135 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| N3.1 - Free-cutting copper-alloys materials with excellent machining properties | Possible use | 64 m/min | 0.119 mm/rev |

| N3.2 - Short-chip copper-alloys with good to moderate machining properties | Possible use | 38 m/min | 0.15 mm/rev |

| N3.3 - Electrolytic copper and long-chip copper-alloys with moderate to poor machining properties | Possible use | 19 m/min | 0.102 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| N4.1 - Thermoplastic polymers | Possible use | 30 m/min | 0.15 mm/rev |

| N4.2 - Thermosetting polymers | Possible use | 35 m/min | 0.119 mm/rev |

| N4.3 - Reinforced polymers or composites | Possible use | 17 m/min | 0.084 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| S1.1 - Titanium or titanium alloys, with a hardness of <200HB | Primary use | 25 m/min | 0.119 mm/rev |

| S1.2 - Titanium alloys, with a hardness of 200 - 280HB | Possible use | 14 m/min | 0.073 mm/rev |

| S1.3 - Titanium alloys, a hardness of 280 - 360HB | Possible use | 8 m/min | 0.044 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| S2.1 - High-temperature Fe-based alloys with a hardness of <200HB | Possible use | 11 m/min | 0.073 mm/rev |

| S2.2 - High-temperature Fe-based alloys with a hardness of 200-280HB | Possible use | 6 m/min | 0.037 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| S3.1 - High-temperature Ni-based alloys with a hardness of <280HB | Possible use | 8 m/min | 0.073 mm/rev |

| S3.2 - High-temperature Ni-based alloys with a hardness of 280 - 360HB | Possible use | 4 m/min | 0.037 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| S4.1 - High-temperature Co-based alloys with a hardness of <240HB | Possible use | 6 m/min | 0.073 mm/rev |

| S4.2 - High-temperature Co-based alloys with a hardness of 240 - 320HB | Possible use | 3 m/min | 0.037 mm/rev |