Bright (uncoated)

E268M26X1.5

MF Machine Tap Straight Flute

Material ID: 5975060

Straight flute tap with chamfer form C with a 2-3xP plug lead, for ISO-Metric Fine thread M26 with 1.50 mm pitch and 6H class of fit, dimensions according to DIN 374 standard with 18.0mm shank and 14.5mm square drive, powder metallurgical HSS-E with bright finish for 1.5xD through or blind hole threading in free machining and plain carbon steel

Product Feature

Thread Form, Metric Fine

DIN 374 – MF Thread Standard

DIN Thread Pitch Diameter Tolerance Zone (high basic pitch diameter)

Through or Blind Hole Application

1.5×D Usable Tool Depth to Diameter Ratio

High Speed Cobalt Powder Metal Tool Material

Semi-Bottoming Tap Chamfer (2 – 3 Pitch Lead)

Straight Flute Geometry

Right Hand Rotation / Cutting

Product Detail

Description | Value |

|---|---|

| Product name | E268M26X1.5 |

| Product number (SAP) | 86015921 |

| EAN number | 7320760088692 |

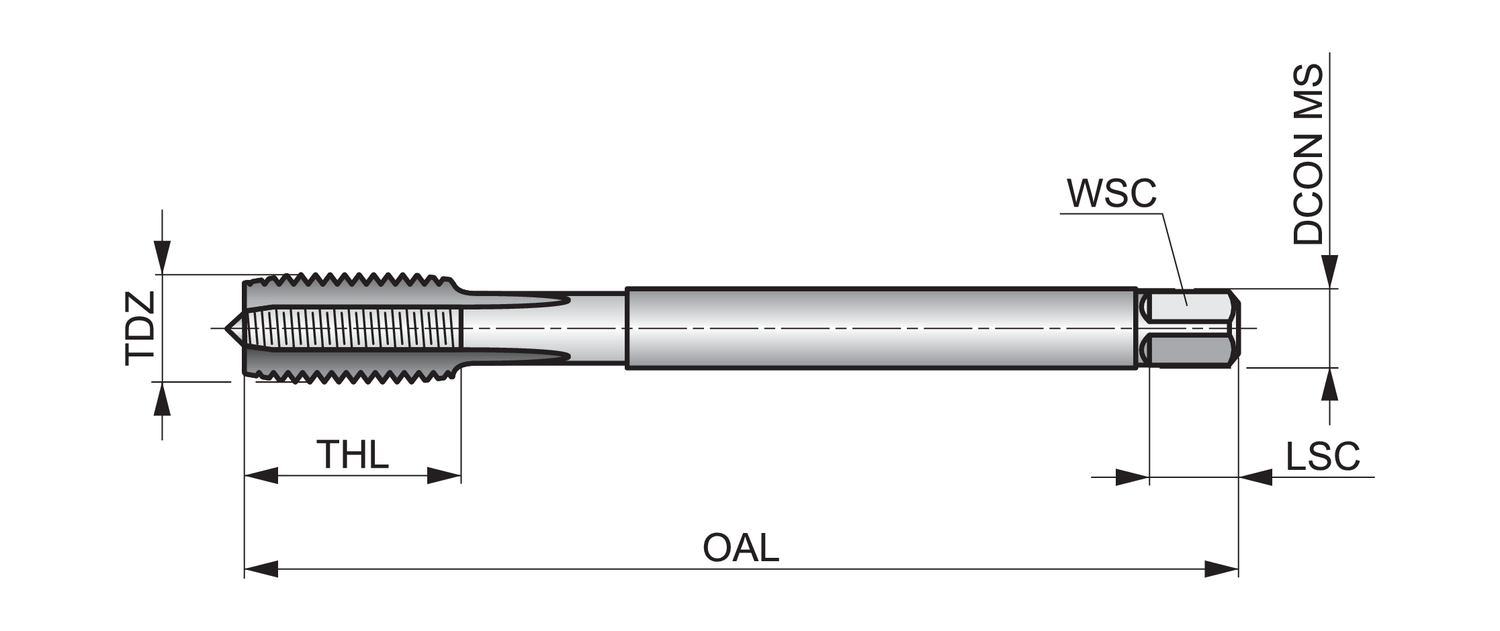

| Thread diameter size (TDZ) | 26 |

| Thread pitch - millimeter (TP) | 1.5 mm |

| Overall length - millimeter (OAL) | 140 mm |

| Overall length - inch (OAL) | 5.5118 inch |

| Threading length - millimeter (THL) | 28 mm |

| Threading length - inch (THL) | 1.1024 inch |

| Connection diameter - inch (DCON MS) | 0.7087 inch |

| Connection diameter - millimeter (DCON MS) | 18 mm |

| Flute count (NOF) | 4 |

| Clamping width - inch (WSC) | 0.5709 inch |

| Clamping width - millimeter (WSC) | 14.5 mm |

| Clamping Length - inch (LCS) | 0.6693 inch |

| Clamping Length - millimeter (LSC) | 17 mm |

| Premachined hole diameter - inch (PHD) | 0.9646 inch |

| Premachined hole diameter - millimeter (PHD) | 24.5 mm |

| Gross weight - grams | 286.4 |

| ISO | E268M26X1.5 |

| Ordering code ANSI | E268M26X1.5 |

Cutting Conditions

| Suitability | vc | f | |

|---|---|---|---|

| P1.1 - Free machining sulfurized carbon steel with a hardness of < 240HB | Primary use | 11 m/min | |

| P1.2 - Free machining sulfurized and phosphorized carbon steel with a hardness of < 180HB | Primary use | 12 m/min | |

| P1.3 - Free machining sulfurized/phosphorized and leaded carbon steel with a hardness of < 180HB | Primary use | 12 m/min |

| Suitability | vc | f | |

|---|---|---|---|

| P2.1 - Plain low carbon steel containing < 0.25%C with a hardness of < 180HB | Primary use | 9 m/min | |

| P2.2 - Plain medium carbon steel containing < 0.55%C with a hardness of < 240HB | Primary use | 8 m/min | |

| P2.3 - Plain high carbon steel containing > 0.55%C, with a hardness of < 300HB | Possible use | 7 m/min |

| Suitability | vc | f | |

|---|---|---|---|

| P3.1 - Alloy steel with a hardness of < 180HB | Primary use | 7 m/min | |

| P3.2 - Alloy steel with a hardness of 180 - 260HB | Possible use | 6 m/min |

| Suitability | vc | f | |

|---|---|---|---|

| P4.1 - Tool steel with a hardness of < 26HRC | Possible use | 4 m/min |

| Suitability | vc | f | |

|---|---|---|---|

| K1.1 - Gray iron, ferritic or ferritic-pearlitic with a hardness of < 180HB | Possible use | 13 m/min | |

| K1.2 - Gray iron, ferritic-pearlitic or pearlitic with a hardness of 180 - 240HB | Possible use | 10 m/min | |

| K1.3 - Gray iron, pearlitic with a hardness of 240 - 280HB | Possible use | 8 m/min |

| Suitability | vc | f | |

|---|---|---|---|

| K2.1 - Malleable iron, ferritic with a hardness of < 160HB | Possible use | 14 m/min | |

| K2.2 - Malleable iron, ferritic or pearlitic with a hardness of 160 - 200HB | Possible use | 11 m/min |

| Suitability | vc | f | |

|---|---|---|---|

| K3.1 - Ductile (nodular/spheriodal) iron, ferritic with a hardness of < 180HB | Possible use | 13 m/min | |

| K3.2 - Ductile (nodular/spheriodal) iron, ferritic or pearlitic with a hardness of 180 - 220HB | Possible use | 10 m/min |

| Suitability | vc | f | |

|---|---|---|---|

| K4.1 - Austenitic cast iron with a hardness of < 180HB | Possible use | 12 m/min | |

| K4.2 - Austenitic cast iron with a hardness of 180 - 240HB | Possible use | 9 m/min |

| Suitability | vc | f | |

|---|---|---|---|

| K5.1 - Vermicular, compacted graphite iron with a hardness of < 180HB | Possible use | 12 m/min | |

| K5.2 - Vermicular, compacted graphite iron with a hardness of 180 - 220HB | Possible use | 10 m/min |

| Suitability | vc | f | |

|---|---|---|---|

| N1.3 - Wrought aluminium alloys with a hardness of 100 - 150HB | Possible use | 12 m/min |

| Suitability | vc | f | |

|---|---|---|---|

| N2.1 - Cast aluminium alloys with a hardness of < 75HB | Possible use | 15 m/min | |

| N2.2 - Cast aluminium alloys with a hardness of 75 - 90HB | Possible use | 14 m/min | |

| N2.3 - Cast aluminium alloys with a hardness of 90 < 140HB | Possible use | 11 m/min |

| Suitability | vc | f | |

|---|---|---|---|

| N3.1 - Free-cutting copper-alloys materials with excellent machining properties | Possible use | 21 m/min | |

| N3.2 - Short-chip copper-alloys with good to moderate machining properties | Primary use | 14 m/min |

| Suitability | vc | f | |

|---|---|---|---|

| N4.2 - Thermosetting polymers | Possible use | 8 m/min |