Titanium Aluminium Nitride Coating

R45711.5

Force X Drill Oil Feed 3×D

Material ID: 5979040

High-performance FORCE X drill with DIN 6535HA NC parallel shank, diameter 11.5mm with an overall length of 102mm and flute length of 55mm according to DIN 6537 K standard with 140° modified 4-facet split point, solid carbide with TiAlN coating, continiously thinned parallel web and through coolant holes for 3xD drilling without pecking in steel, stainless steel, cast iron, non-ferrous material, super-alloy and hardened material

Product Feature

Hard Material (Solid Carbide)

DIN 6537 K

3×D Usable Tool Depth to Diameter Ratio

Drill Point 140°

DIN 6535 HA Cylindrical Shank

Continuously Thinned Web Flute Design

Through Tool Coolant

m7 – Industry Standard Tool Tolerance Zone (based on diameter range)

Product Detail

Description | Value |

|---|---|

| EAN number | 7320760614761 |

| Product number (SAP) | 86019372 |

| Ordering code ANSI | R45711.5 |

| Product Line | FORCE X |

| Gross weight - grams | 120 |

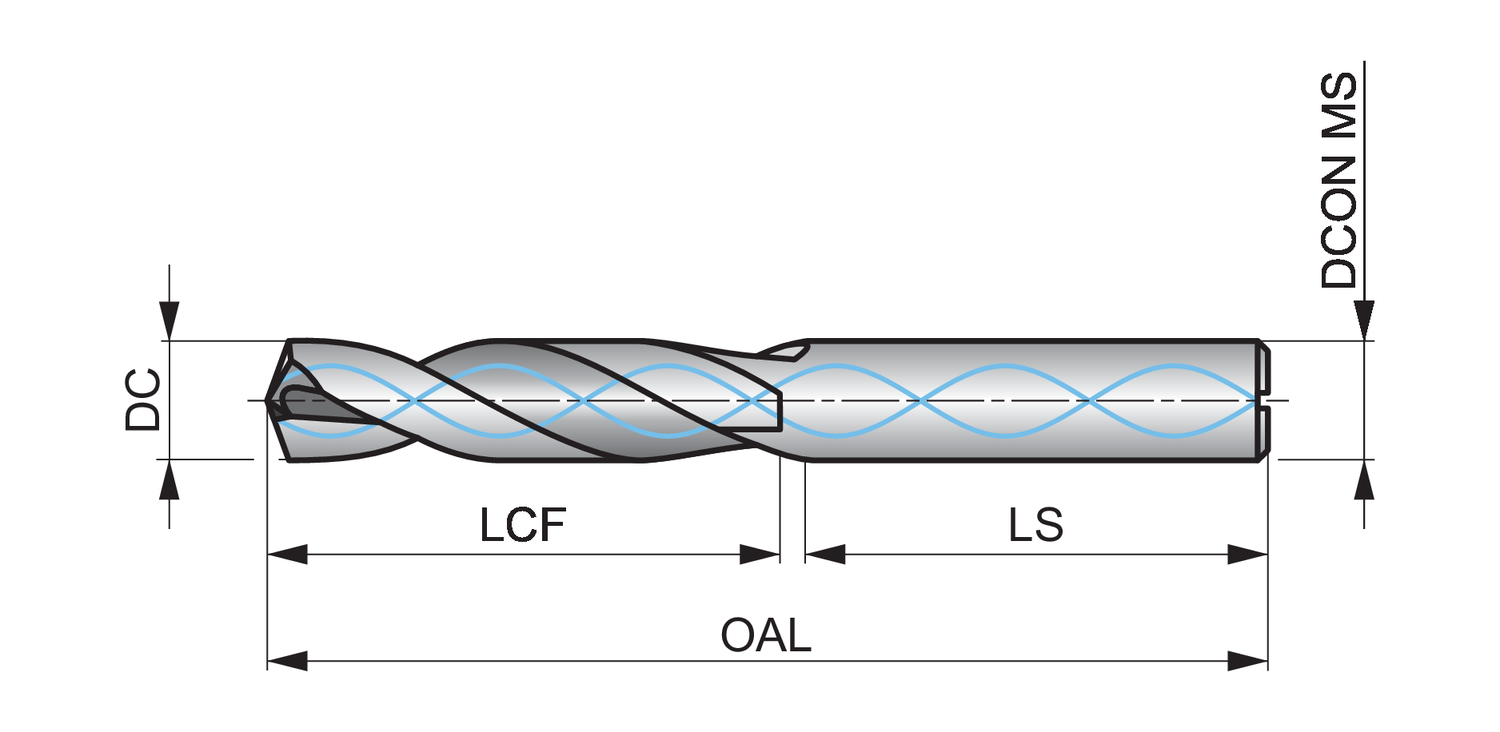

| Cutting diameter - millimeter (DC) | 11.5 mm |

| Cutting diameter - inch (DC) | 0.4528 inch |

| Length chip flute - millimeter (LCF) | 55 mm |

| Overall length - millimeter (OAL) | 102 mm |

| Shank length - millimeter (LS) | 45 mm |

| Connection diameter - millimeter (DCON MS) | 12 mm |

| Length chip flute - inch (LCF) | 2.1654 inch |

| ISO | R45711.5 |

Features & benefits

- Ttanium Aluminium Nitride coating increases surface hardness and wear resistance at higher temperatures to improve tool life at accelerated cutting data

- Micrograin Carbide providing extreme hardness and wear resistance providing increased tool life when machining difficult materials

- Continuously Thinned Web design provides a strong web whilst reducing axial forces, giving a very secure, predictable tool life and helping make re-conditioning easier

Cutting Conditions

| Suitability | vc | f | |

|---|---|---|---|

| P1.1 - Free machining sulfurized carbon steel with a hardness of < 240HB | Primary use | 179 m/min | 0.367 mm/rev |

| P1.2 - Free machining sulfurized and phosphorized carbon steel with a hardness of < 180HB | Primary use | 200 m/min | 0.367 mm/rev |

| P1.3 - Free machining sulfurized/phosphorized and leaded carbon steel with a hardness of < 180HB | Primary use | 207 m/min | 0.367 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| P2.1 - Plain low carbon steel containing < 0.25%C with a hardness of < 180HB | Primary use | 153 m/min | 0.367 mm/rev |

| P2.2 - Plain medium carbon steel containing < 0.55%C with a hardness of < 240HB | Primary use | 135 m/min | 0.367 mm/rev |

| P2.3 - Plain high carbon steel containing > 0.55%C, with a hardness of < 300HB | Primary use | 119 m/min | 0.272 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| P3.1 - Alloy steel with a hardness of < 180HB | Primary use | 133 m/min | 0.272 mm/rev |

| P3.2 - Alloy steel with a hardness of 180 - 260HB | Primary use | 107 m/min | 0.272 mm/rev |

| P3.3 - Alloy steel with a hardness of 260 - 360HB | Primary use | 90 m/min | 0.272 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| P4.1 - Tool steel with a hardness of < 26HRC | Primary use | 79 m/min | 0.272 mm/rev |

| P4.2 - Tool steel with a hardness of 26 - 39RC | Primary use | 67 m/min | 0.272 mm/rev |

| P4.3 - Tool steel with a hardness of 39 - 45HRC | Primary use | 55 m/min | 0.193 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M1.1 - Stainless steel, ferritic with a hardness of < 160HB | Possible use | 75 m/min | 0.272 mm/rev |

| M1.2 - Stainless steel, ferritic with a hardness of 160 - 220HB | Possible use | 64 m/min | 0.272 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M2.1 - Stainless steel, martensitic with a hardness of < 200HB | Possible use | 67 m/min | 0.272 mm/rev |

| M2.2 - Stainless steel, martensitic with a hardness of 200 - 280HB | Possible use | 55 m/min | 0.272 mm/rev |

| M2.3 - Stainless steel, martensitic with a hardness of 280 - 380HB | Possible use | 46 m/min | 0.193 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M3.1 - Stainless steel, austenitic with a hardness of < 200HB | Possible use | 41 m/min | 0.272 mm/rev |

| M3.2 - Stainless steel, austenitic with a hardness of 200 - 260HB | Possible use | 35 m/min | 0.272 mm/rev |

| M3.3 - Stainless steel, austenitic with a hardness of 260 - 300HB | Possible use | 32 m/min | 0.272 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M4.1 - Stainless steel, austenitic-ferritic or super-austenitic with a hardness of < 300HB | Possible use | 30 m/min | 0.193 mm/rev |

| M4.2 - Stainless steel, precipitation hardening austenitic with a hardness of 300 - 380HB | Possible use | 26 m/min | 0.193 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K1.1 - Gray iron, ferritic or ferritic-pearlitic with a hardness of < 180HB | Primary use | 110 m/min | 0.367 mm/rev |

| K1.2 - Gray iron, ferritic-pearlitic or pearlitic with a hardness of 180 - 240HB | Primary use | 81 m/min | 0.367 mm/rev |

| K1.3 - Gray iron, pearlitic with a hardness of 240 - 280HB | Primary use | 61 m/min | 0.367 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K2.1 - Malleable iron, ferritic with a hardness of < 160HB | Primary use | 98 m/min | 0.272 mm/rev |

| K2.2 - Malleable iron, ferritic or pearlitic with a hardness of 160 - 200HB | Primary use | 80 m/min | 0.272 mm/rev |

| K2.3 - Malleable iron, pearlitic with a hardness of 200 - 240HB | Primary use | 64 m/min | 0.272 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K3.1 - Ductile (nodular/spheriodal) iron, ferritic with a hardness of < 180HB | Primary use | 87 m/min | 0.272 mm/rev |

| K3.2 - Ductile (nodular/spheriodal) iron, ferritic or pearlitic with a hardness of 180 - 220HB | Primary use | 67 m/min | 0.272 mm/rev |

| K3.3 - Ductile (nodular/spheriodal) iron, pearlitic with a hardness of 220 - 260HB | Primary use | 54 m/min | 0.272 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K4.1 - Austenitic cast iron with a hardness of < 180HB | Primary use | 81 m/min | 0.272 mm/rev |

| K4.2 - Austenitic cast iron with a hardness of 180 - 240HB | Primary use | 61 m/min | 0.272 mm/rev |

| K4.3 - Austempered ductile iron with a hardness of 240 - 280HB | Primary use | 45 m/min | 0.272 mm/rev |

| K4.4 - Austempered ductile iron with a hardness of 280 - 320HB | Primary use | 38 m/min | 0.272 mm/rev |

| K4.5 - Austempered ductile iron with a hardness of 320 - 360HB | Primary use | 32 m/min | 0.272 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K5.1 - Vermicular, compacted graphite iron with a hardness of < 180HB | Primary use | 91 m/min | 0.272 mm/rev |

| K5.2 - Vermicular, compacted graphite iron with a hardness of 180 - 220HB | Primary use | 69 m/min | 0.272 mm/rev |

| K5.3 - Vermicular, compacted graphite iron with a hardness of 220 - 260HB | Primary use | 53 m/min | 0.272 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| N1.1 - Pure aluminium and wrought aluminium alloys with a hardness of < 60HB | Primary use | 250 m/min | 0.367 mm/rev |

| N1.2 - Wrought aluminium alloys with a hardness of 60 - 100HB | Primary use | 188 m/min | 0.367 mm/rev |

| N1.3 - Wrought aluminium alloys with a hardness of 100 - 150HB | Primary use | 125 m/min | 0.367 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| N2.1 - Cast aluminium alloys with a hardness of < 75HB | Primary use | 308 m/min | 0.272 mm/rev |

| N2.2 - Cast aluminium alloys with a hardness of 75 - 90HB | Primary use | 277 m/min | 0.272 mm/rev |

| N2.3 - Cast aluminium alloys with a hardness of 90 < 140HB | Primary use | 200 m/min | 0.272 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| N3.1 - Free-cutting copper-alloys materials with excellent machining properties | Primary use | 373 m/min | 0.367 mm/rev |

| N3.2 - Short-chip copper-alloys with good to moderate machining properties | Primary use | 220 m/min | 0.367 mm/rev |

| N3.3 - Electrolytic copper and long-chip copper-alloys with moderate to poor machining properties | Primary use | 110 m/min | 0.367 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| S1.1 - Titanium or titanium alloys, with a hardness of <200HB | Primary use | 55 m/min | 0.272 mm/rev |

| S1.2 - Titanium alloys, with a hardness of 200 - 280HB | Primary use | 45 m/min | 0.272 mm/rev |

| S1.3 - Titanium alloys, a hardness of 280 - 360HB | Primary use | 40 m/min | 0.193 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| H1.1 - Chilled cast iron with a hardness of <440HB | Primary use | 56 m/min | 0.193 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| H2.1 - Hardened cast iron with a hardness <55HRC | Possible use | 33 m/min | 0.193 mm/rev |

| H2.2 - Hardened cast iron with a hardness >55HRC | Possible use | 30 m/min | 0.193 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| H3.1 - Hardened steel with a hardness of <51HRC | Possible use | 37 m/min | 0.193 mm/rev |

| H3.2 - Hardened steel with a hardness of 51 - 55HRC | Possible use | 30 m/min | 0.193 mm/rev |