Titanium Silicon Nitride Coating

S52612.0

Finishing End Mill

Material ID: 6706794

Long series finishing end mill with 6 flutes, diameter 12mm with 50mm length of cut, 100mm overall length and 60mm reach with neck relief, according to DORMER standard with a 12mm plain shank, solid carbide with TiSiN coating, 50° helix and -26° rake angle for shoulder milling in hardened materials

Product Feature

Hard Material (Solid Carbide)

General Purpose Cutter Type for Low to High Resistance Materials

Cut Length, Long

50° Helix Angle (Flute)

DIN 6535 HA Cylindrical Shank

h9 – Industry Standard Tool Tolerance Zone (based on diameter range)

Radial

Dormer Standards

Number of Flutes = 6 (teeth)

Product Operation

Deep Shoulder Milling - Primary use

Product Detail

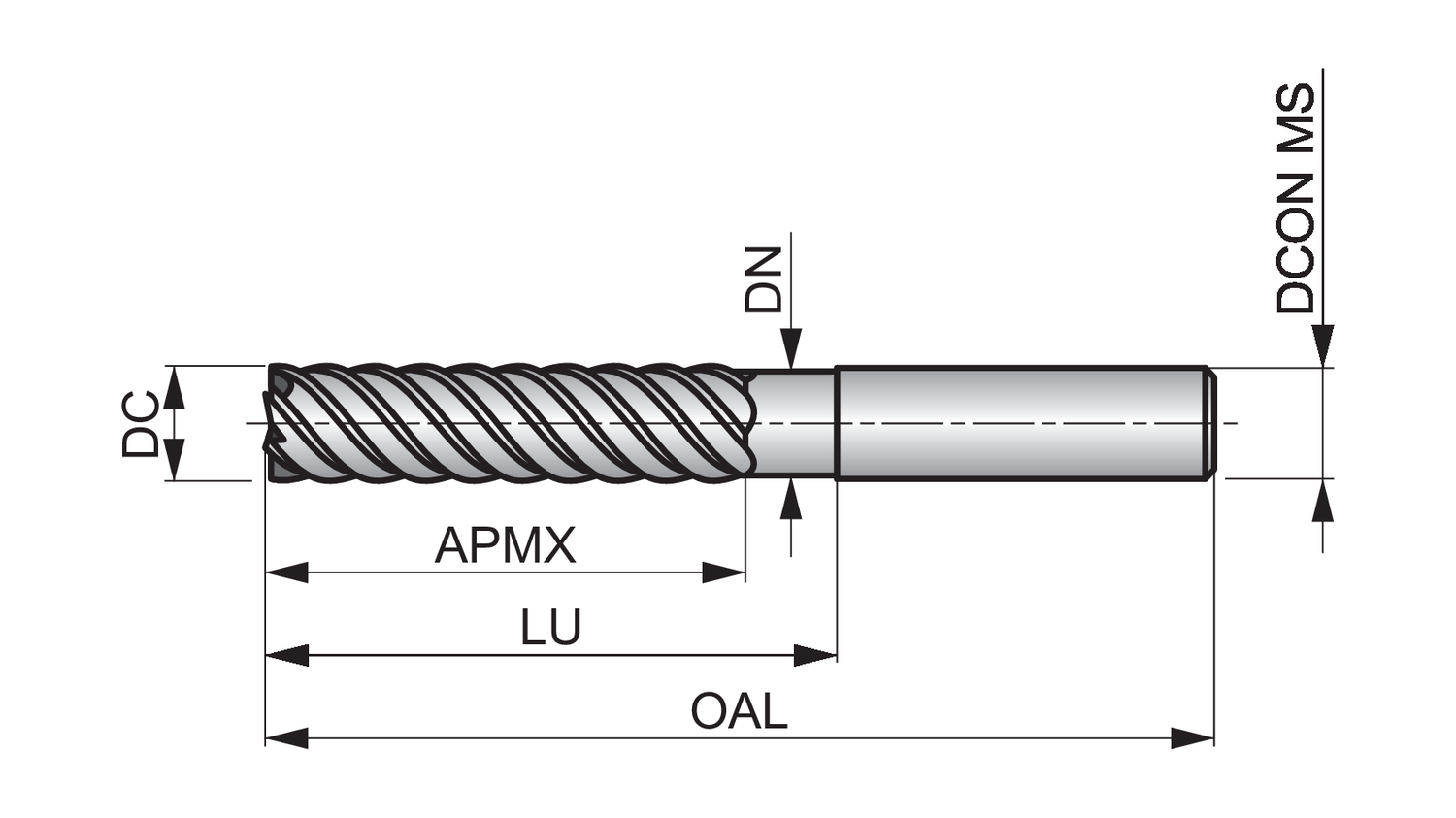

Description | Value |

|---|---|

| EAN number | 7320760683439 |

| Product number (SAP) | 86021931 |

| Ordering code ANSI | S52612.0 |

| Gross weight - grams | 148 |

| Cutting diameter - millimeter (DC) | 12 mm |

| Connection diameter - millimeter (DCON MS) | 12 mm |

| Depth of cut maximum - millimeter (APMX) | 50 mm |

| Overall length - millimeter (OAL) | 100 mm |

| Flute count (NOF) | 6 |

| Usable Length - millimeter (LU) | 60 mm |

| Neck diameter - millimeter (DN) | 11 mm |

| Radial rake angle (GAMF) | -26 |

| With Neck | Yes |

| ISO | S52612.0 |

Cutting Conditions

| Suitability | vc | f | |

|---|---|---|---|

| H1.1 - Chilled cast iron with a hardness of <440HB | Primary use | 96 m/min | 0.039 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| H2.1 - Hardened cast iron with a hardness <55HRC | Primary use | 57 m/min | 0.032 mm/rev |

| H2.2 - Hardened cast iron with a hardness >55HRC | Primary use | 49 m/min | 0.019 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| H3.1 - Hardened steel with a hardness of <51HRC | Primary use | 63 m/min | 0.032 mm/rev |

| H3.2 - Hardened steel with a hardness of 51 - 55HRC | Primary use | 52 m/min | 0.032 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| H4.1 - Hardened steel with a hardness of 55 - 59HRC | Primary use | 40 m/min | 0.019 mm/rev |

| H4.2 - Hardened steel with a hardness of >59HRC | Primary use | 34 m/min | 0.014 mm/rev |