Features and benefits

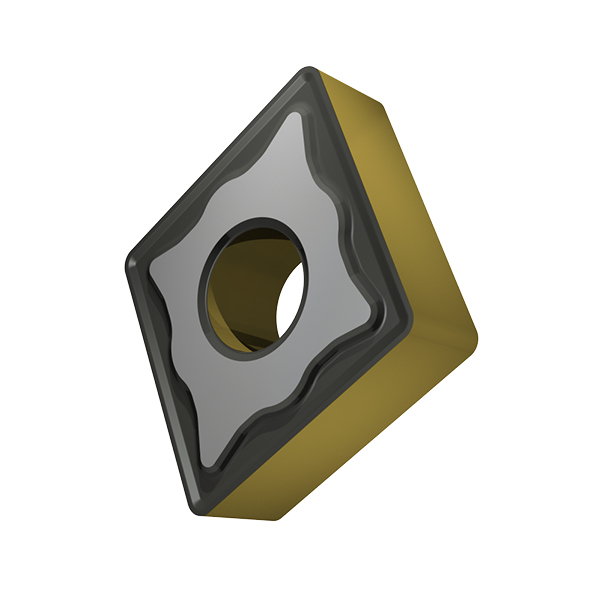

| Thick MT-CVD coating layer enhances resistance to flank wear, crater wear, and plastic deformation. | → |

Extended tool life

significantly increases productivity.

|

| The α-Al₂O₃ coating provides superior wear resistance and thermal stability. | → |

Precise cutting performance

improves efficiency in demanding operations.

|

| New post-treatment process improves stability of cutting edge. | → |

Enhanced reliability

especially in unstable conditions.

|

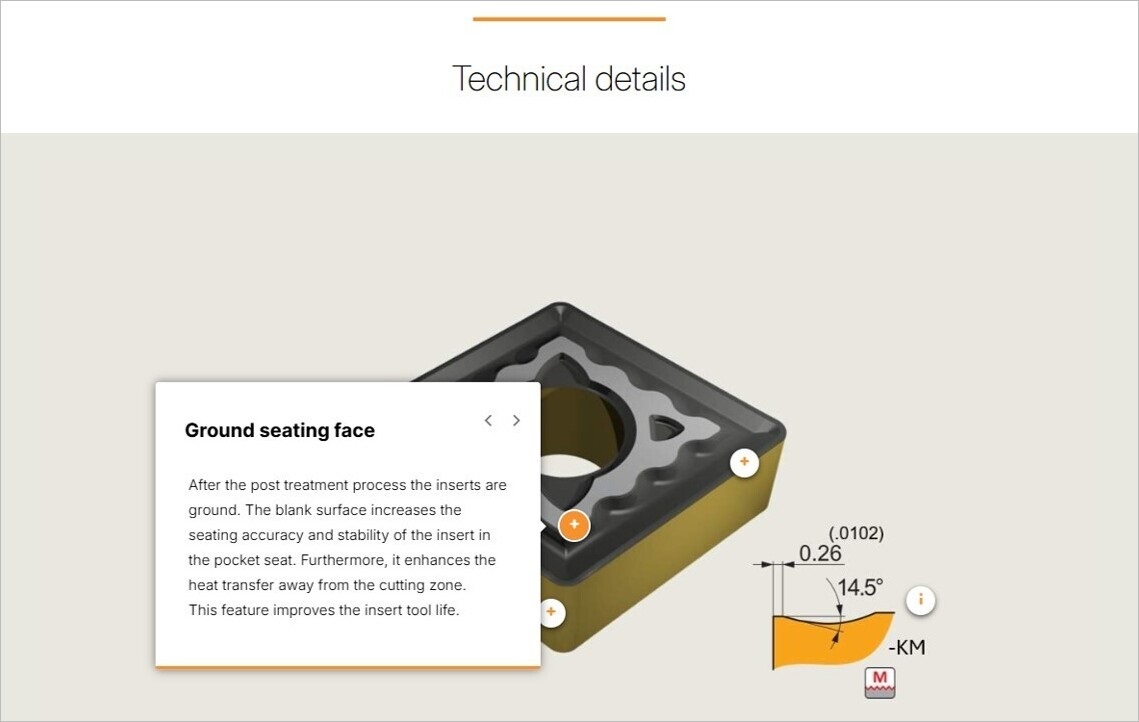

| Ground seating face provides larger contact area and optimizes heat transfer. | → |

Improved seating stability

ensures consistent high-quality performance.

|

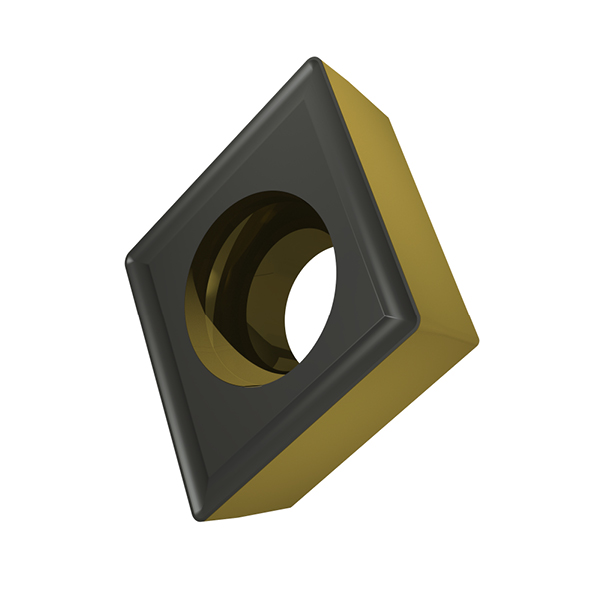

| Gold colored TiN coating on flanks helps with monitoring tool condition effectively. | → |

Easier wear detection

reduces downtime.

|

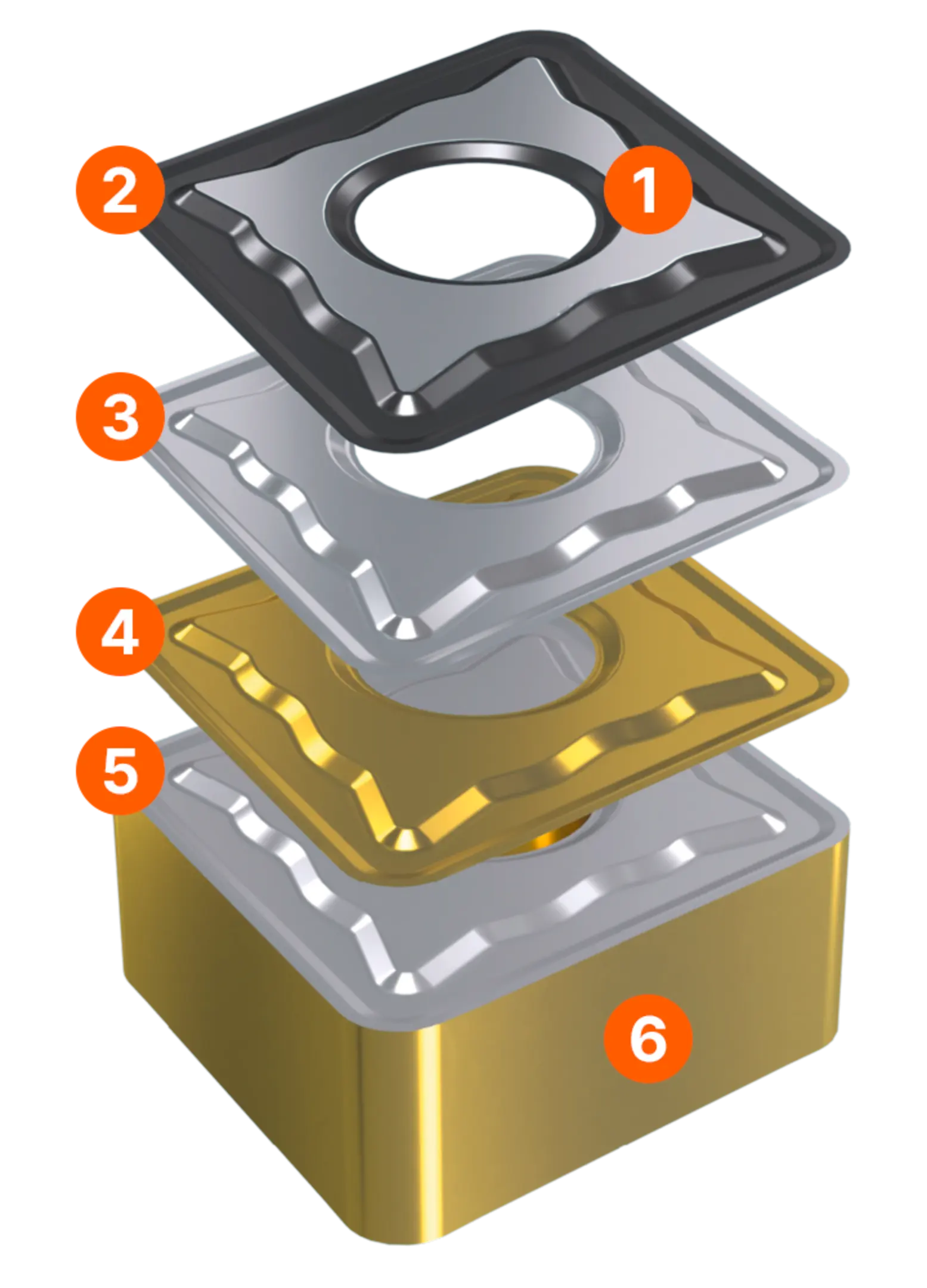

30% thicker coating for enhanced durability

Grade composition

1. Ground seating face

2. Abrasion and heat resistant Al₂O₃

3. Abrasion resistant TiCN layer

4. Adhesive TiN layer

5. Substrate

6. Gold colored TiN layer

Explore our new T5415 grade

T5415

T5415

Superior performance for nodular cast iron machining

T5415 sets a new benchmark in nodular cast iron machining, offering up to 90% longer tool life than competitors. With 23.3 minutes of continual turning, it reduces downtime, lowers tool changes, and boosts productivity, making it ideal for demanding industrial applications.

Boost durability by 87.5% for roughing and 57% for finishing operations

Customer result: The T5415 grade delivered unmatched efficiency in critical applications. For internal roughing with interrupted cutting, it boosted durabilty by 87.5%, adding seven extra workpieces. In finishing operations, it increased output by 57%, achieving 33 workpieces versus 21 with standard tools.

New T5415 grade

In this brief e-learning, you receive an overview of our high performance turning grade.

Our promise

Certainty at every turn.

Together we will keep our world turning, now and into the future. We want to help our community feel confident they can get the job done with simplified access to the right advice, tools and training whenever and wherever they need it. Delivering certainty to help our customers achieve their goals today – and be ready for tomorrow.