Aluminium Titanium Nitride Coating

S223HB1/2XR.030

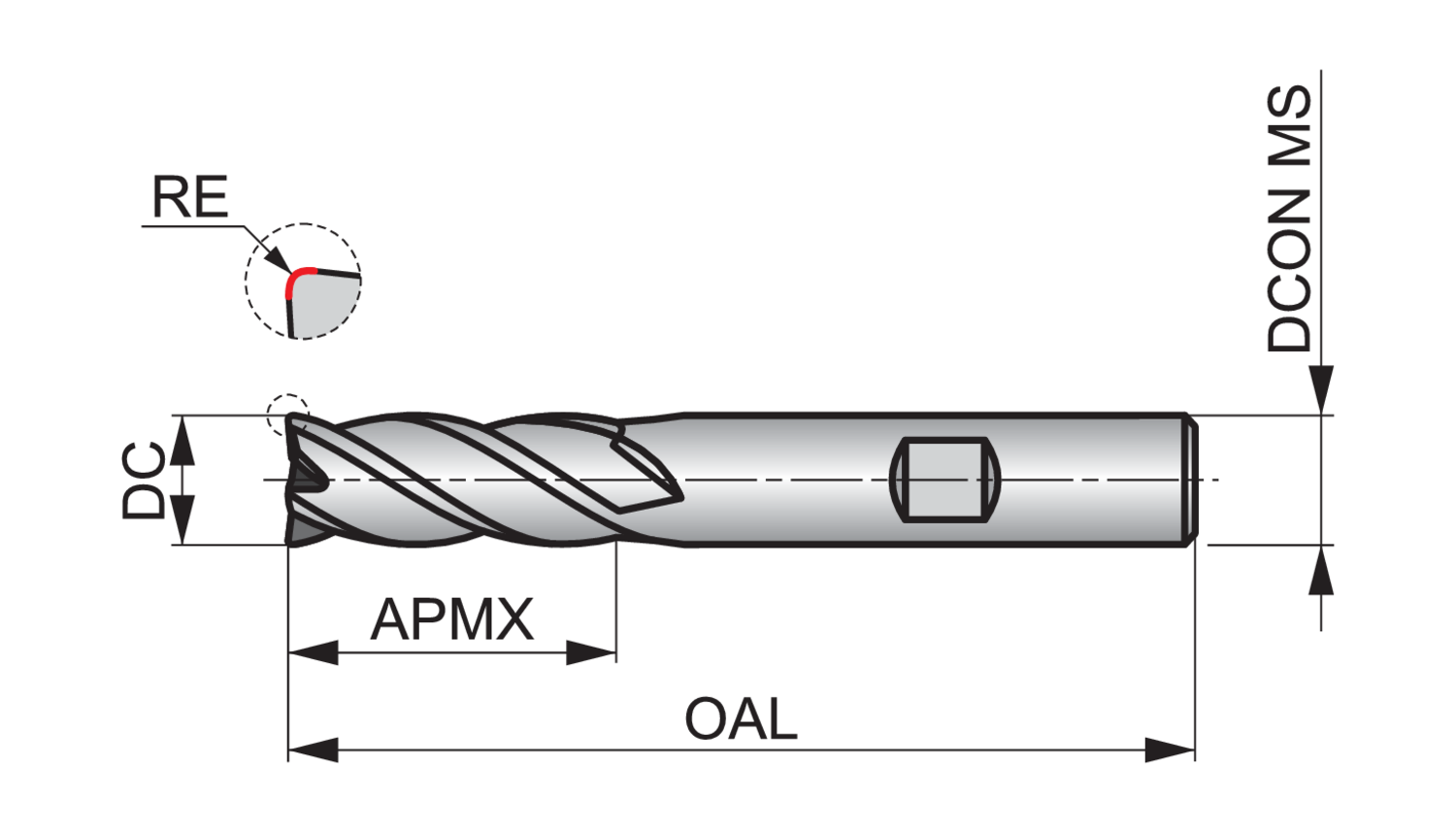

Corner Radius End Mill

Material ID: 7648709

Regular length corner radius end mill with 4 flutes, diameter 1/2" with 1.1/4" length of cut, 3" overall length and 0.03" corner radii, according to DORMER standard with a 1/2" Weldon shank, solid carbide with AlTiN coating, unequal helix for shoulder milling, plunging, progressive plunge milling, ramping, helical milling and trochoidal milling in steel and cast steel, stainless steel, cast-iron, high-temperature alloys, chilled, hardened cast-iron and hardened steel <55HRC

Product Feature

Hard Material (Solid Carbide)

General Purpose Cutter Type for Low to High Resistance Materials

Number of Flutes = 4 (teeth)

Cut Length, Medium

Unequal (Variable) Helix

DIN 6535 HB Weldon Shank

Dormer Standards

Product Operation

Face Milling - Possible use

Shallow Shoulder Milling - Primary use

Deep Shoulder Milling - Possible use

Plunge Milling - Primary use

Shallow Slot Milling - Possible use

Ramping - Primary use

Progressive Plunging - Primary use

Helical Interpolation - Primary use

Trochoidal Milling - Possible use

Product Detail

Description | Value |

|---|---|

| EAN number | 7320760847565 |

| Product number (SAP) | 86035999 |

| Ordering code ANSI | S223HB1/2XR.030 |

| Gross weight - grams | 116 |

| Flute helix unequal | Yes |

| Connection diameter - fractional inch (DCON MS) | 1/2 |

| Connection diameter - millimeter (DCON MS) | 12.7 mm |

| Cutting diameter - fractional inch (DC) | 1/2 |

| Cutting diameter - millimeter (DC) | 12.7 mm |

| Overall length - fractional inch (OAL) | 3" |

| Overall length - millimeter (OAL) | 76.2 mm |

| ISO | S223HB1/2XR.030 |

Cutting Conditions

| Suitability | vc | f | |

|---|---|---|---|

| P1.1 - Free machining sulfurized carbon steel with a hardness of < 240HB | Primary use | 212 m/min | 0.068 mm/rev |

| P1.2 - Free machining sulfurized and phosphorized carbon steel with a hardness of < 180HB | Primary use | 237 m/min | 0.068 mm/rev |

| P1.3 - Free machining sulfurized/phosphorized and leaded carbon steel with a hardness of < 180HB | Primary use | 244 m/min | 0.068 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| P2.1 - Plain low carbon steel containing < 0.25%C with a hardness of < 180HB | Primary use | 181 m/min | 0.068 mm/rev |

| P2.2 - Plain medium carbon steel containing < 0.55%C with a hardness of < 240HB | Primary use | 159 m/min | 0.068 mm/rev |

| P2.3 - Plain high carbon steel containing > 0.55%C, with a hardness of < 300HB | Primary use | 141 m/min | 0.056 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| P3.1 - Alloy steel with a hardness of < 180HB | Primary use | 147 m/min | 0.068 mm/rev |

| P3.2 - Alloy steel with a hardness of 180 - 260HB | Primary use | 118 m/min | 0.056 mm/rev |

| P3.3 - Alloy steel with a hardness of 260 - 360HB | Primary use | 100 m/min | 0.056 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| P4.1 - Tool steel with a hardness of < 26HRC | Primary use | 87 m/min | 0.056 mm/rev |

| P4.2 - Tool steel with a hardness of 26 - 39RC | Primary use | 74 m/min | 0.056 mm/rev |

| P4.3 - Tool steel with a hardness of 39 - 45HRC | Primary use | 60 m/min | 0.056 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M1.1 - Stainless steel, ferritic with a hardness of < 160HB | Primary use | 149 m/min | 0.068 mm/rev |

| M1.2 - Stainless steel, ferritic with a hardness of 160 - 220HB | Primary use | 126 m/min | 0.068 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M2.1 - Stainless steel, martensitic with a hardness of < 200HB | Primary use | 132 m/min | 0.068 mm/rev |

| M2.2 - Stainless steel, martensitic with a hardness of 200 - 280HB | Primary use | 109 m/min | 0.056 mm/rev |

| M2.3 - Stainless steel, martensitic with a hardness of 280 - 380HB | Primary use | 92 m/min | 0.056 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M3.1 - Stainless steel, austenitic with a hardness of < 200HB | Primary use | 122 m/min | 0.056 mm/rev |

| M3.2 - Stainless steel, austenitic with a hardness of 200 - 260HB | Primary use | 105 m/min | 0.056 mm/rev |

| M3.3 - Stainless steel, austenitic with a hardness of 260 - 300HB | Primary use | 94 m/min | 0.05 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M4.1 - Stainless steel, austenitic-ferritic or super-austenitic with a hardness of < 300HB | Primary use | 92 m/min | 0.05 mm/rev |

| M4.2 - Stainless steel, precipitation hardening austenitic with a hardness of 300 - 380HB | Primary use | 78 m/min | 0.05 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K1.1 - Gray iron, ferritic or ferritic-pearlitic with a hardness of < 180HB | Primary use | 235 m/min | 0.068 mm/rev |

| K1.2 - Gray iron, ferritic-pearlitic or pearlitic with a hardness of 180 - 240HB | Primary use | 174 m/min | 0.068 mm/rev |

| K1.3 - Gray iron, pearlitic with a hardness of 240 - 280HB | Primary use | 131 m/min | 0.068 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K2.1 - Malleable iron, ferritic with a hardness of < 160HB | Primary use | 242 m/min | 0.068 mm/rev |

| K2.2 - Malleable iron, ferritic or pearlitic with a hardness of 160 - 200HB | Primary use | 197 m/min | 0.068 mm/rev |

| K2.3 - Malleable iron, pearlitic with a hardness of 200 - 240HB | Primary use | 157 m/min | 0.056 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K3.1 - Ductile (nodular/spheriodal) iron, ferritic with a hardness of < 180HB | Primary use | 214 m/min | 0.068 mm/rev |

| K3.2 - Ductile (nodular/spheriodal) iron, ferritic or pearlitic with a hardness of 180 - 220HB | Primary use | 164 m/min | 0.068 mm/rev |

| K3.3 - Ductile (nodular/spheriodal) iron, pearlitic with a hardness of 220 - 260HB | Primary use | 132 m/min | 0.056 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K4.1 - Austenitic cast iron with a hardness of < 180HB | Primary use | 198 m/min | 0.056 mm/rev |

| K4.2 - Austenitic cast iron with a hardness of 180 - 240HB | Primary use | 150 m/min | 0.056 mm/rev |

| K4.3 - Austempered ductile iron with a hardness of 240 - 280HB | Primary use | 110 m/min | 0.056 mm/rev |

| K4.4 - Austempered ductile iron with a hardness of 280 - 320HB | Primary use | 94 m/min | 0.05 mm/rev |

| K4.5 - Austempered ductile iron with a hardness of 320 - 360HB | Primary use | 78 m/min | 0.05 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K5.1 - Vermicular, compacted graphite iron with a hardness of < 180HB | Primary use | 224 m/min | 0.056 mm/rev |

| K5.2 - Vermicular, compacted graphite iron with a hardness of 180 - 220HB | Primary use | 169 m/min | 0.056 mm/rev |

| K5.3 - Vermicular, compacted graphite iron with a hardness of 220 - 260HB | Primary use | 131 m/min | 0.056 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| S1.1 - Titanium or titanium alloys, with a hardness of <200HB | Primary use | 159 m/min | 0.056 mm/rev |

| S1.2 - Titanium alloys, with a hardness of 200 - 280HB | Primary use | 141 m/min | 0.056 mm/rev |

| S1.3 - Titanium alloys, a hardness of 280 - 360HB | Primary use | 118 m/min | 0.05 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| S2.1 - High-temperature Fe-based alloys with a hardness of <200HB | Primary use | 109 m/min | 0.05 mm/rev |

| S2.2 - High-temperature Fe-based alloys with a hardness of 200-280HB | Primary use | 96 m/min | 0.05 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| S3.1 - High-temperature Ni-based alloys with a hardness of <280HB | Primary use | 82 m/min | 0.05 mm/rev |

| S3.2 - High-temperature Ni-based alloys with a hardness of 280 - 360HB | Primary use | 68 m/min | 0.05 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| S4.1 - High-temperature Co-based alloys with a hardness of <240HB | Primary use | 64 m/min | 0.05 mm/rev |

| S4.2 - High-temperature Co-based alloys with a hardness of 240 - 320HB | Primary use | 55 m/min | 0.05 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| H1.1 - Chilled cast iron with a hardness of <440HB | Primary use | 106 m/min | 0.045 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| H2.1 - Hardened cast iron with a hardness <55HRC | Primary use | 63 m/min | 0.037 mm/rev |

| H2.2 - Hardened cast iron with a hardness >55HRC | Possible use | 54 m/min | 0.022 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| H3.1 - Hardened steel with a hardness of <51HRC | Primary use | 70 m/min | 0.037 mm/rev |

| H3.2 - Hardened steel with a hardness of 51 - 55HRC | Primary use | 57 m/min | 0.037 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| H4.1 - Hardened steel with a hardness of 55 - 59HRC | Possible use | 45 m/min | 0.022 mm/rev |

| H4.2 - Hardened steel with a hardness of >59HRC | Possible use | 38 m/min | 0.013 mm/rev |