Special TiAlN Coating (+ Silicon + Chromium)

R9501.5/8

Hydra Drill Head for Steel

Material ID: 6104549

High-performance replaceable drill head HYDRA P, diameter 1.6250" (1.5/8) according to DORMER standard with 140° modified 4-facet split point, solid carbide with Ti-phon coating for drilling steel in combination with HYDRA body size 42.5mm, H853 for up to 3xD, H855 for up to 5xD or H858 for up to 8xD

Product Feature

Hard Material (Solid Carbide)

Dormer Standards

Drill Point 140°

Right Hand Rotation / Cutting

Through Tool Coolant

h7 – Industry Standard Tool Tolerance Zone (based on diameter range)

Product Detail

Description | Value |

|---|---|

| Ordering code ANSI | R9501.5/8 |

| EAN number | 7320760652343 |

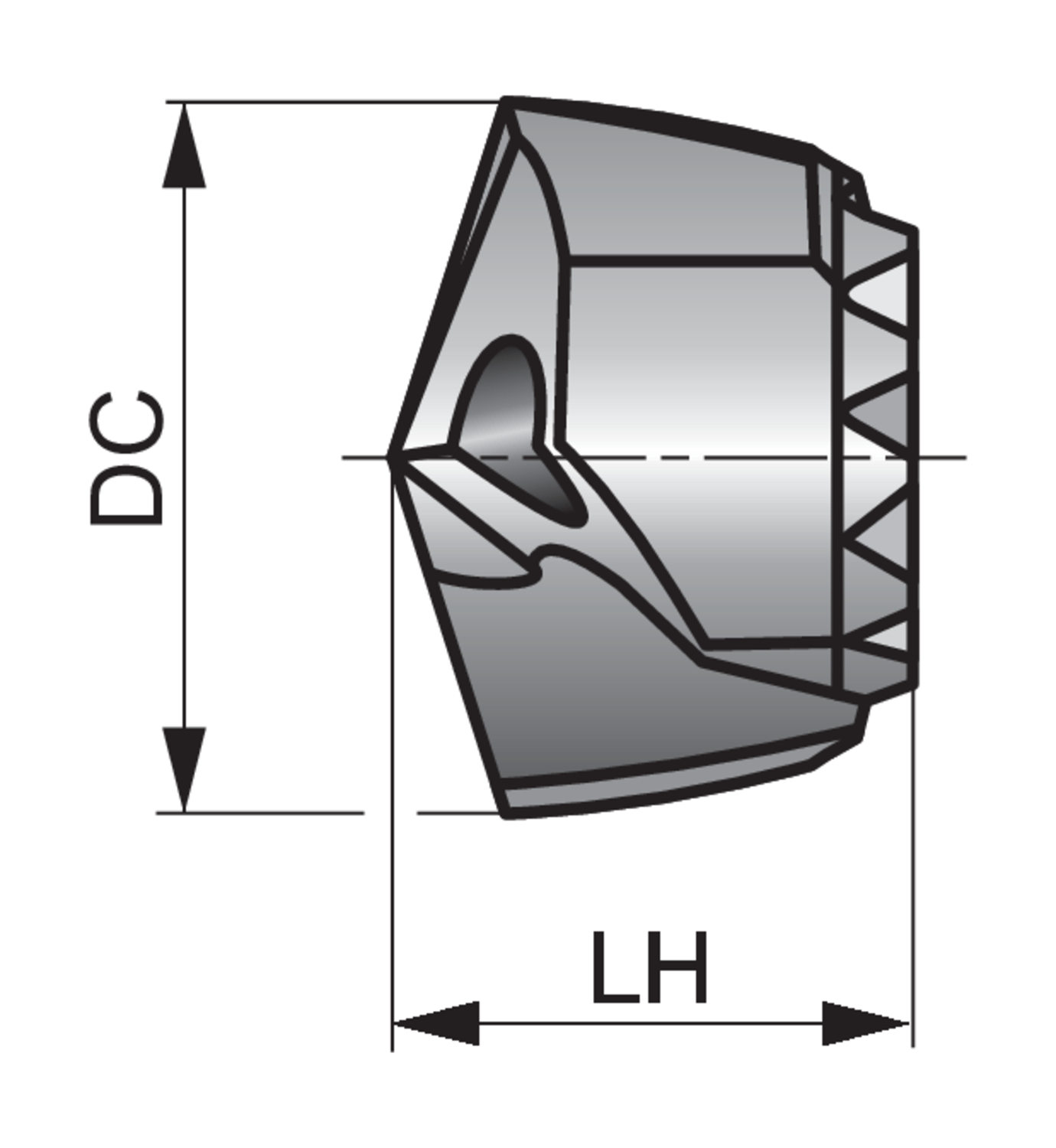

| Cutting diameter - fractional inch (DC) | 1.5/8 |

| Cutting diameter - inch (DC) | 1.625 inch |

| Cutting diameter - millimeter (DC) | 41.28 mm |

| Head length - millimeter (LH) | 27 mm |

| Product Line | HYDRA |

| ISO | R9501.5/8 |

| Brand Name | Dormer Pramet |

| Gross weight - grams | 203 |

| Product number (SAP) | 80023964 |

Cutting Conditions

| Suitability | vc | f | |

|---|---|---|---|

| P1.1 - Free machining sulfurized carbon steel with a hardness of < 240HB | Possible use | 133 m/min | 0.523 mm/rev |

| P1.2 - Free machining sulfurized and phosphorized carbon steel with a hardness of < 180HB | Possible use | 148 m/min | 0.523 mm/rev |

| P1.3 - Free machining sulfurized/phosphorized and leaded carbon steel with a hardness of < 180HB | Possible use | 154 m/min | 0.523 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| P2.1 - Plain low carbon steel containing < 0.25%C with a hardness of < 180HB | Possible use | 114 m/min | 0.523 mm/rev |

| P2.2 - Plain medium carbon steel containing < 0.55%C with a hardness of < 240HB | Primary use | 100 m/min | 0.523 mm/rev |

| P2.3 - Plain high carbon steel containing > 0.55%C, with a hardness of < 300HB | Primary use | 88 m/min | 0.523 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| P3.1 - Alloy steel with a hardness of < 180HB | Primary use | 125 m/min | 0.523 mm/rev |

| P3.2 - Alloy steel with a hardness of 180 - 260HB | Primary use | 101 m/min | 0.523 mm/rev |

| P3.3 - Alloy steel with a hardness of 260 - 360HB | Primary use | 85 m/min | 0.523 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| P4.1 - Tool steel with a hardness of < 26HRC | Primary use | 75 m/min | 0.523 mm/rev |

| P4.2 - Tool steel with a hardness of 26 - 39RC | Primary use | 63 m/min | 0.523 mm/rev |

| P4.3 - Tool steel with a hardness of 39 - 45HRC | Primary use | 52 m/min | 0.262 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M2.3 - Stainless steel, martensitic with a hardness of 280 - 380HB | Possible use | 41 m/min | 0.262 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M4.2 - Stainless steel, precipitation hardening austenitic with a hardness of 300 - 380HB | Possible use | 35 m/min | 0.262 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K2.1 - Malleable iron, ferritic with a hardness of < 160HB | Primary use | 108 m/min | 0.513 mm/rev |

| K2.2 - Malleable iron, ferritic or pearlitic with a hardness of 160 - 200HB | Primary use | 88 m/min | 0.513 mm/rev |

| K2.3 - Malleable iron, pearlitic with a hardness of 200 - 240HB | Primary use | 70 m/min | 0.513 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K3.1 - Ductile (nodular/spheriodal) iron, ferritic with a hardness of < 180HB | Primary use | 96 m/min | 0.513 mm/rev |

| K3.2 - Ductile (nodular/spheriodal) iron, ferritic or pearlitic with a hardness of 180 - 220HB | Primary use | 73 m/min | 0.513 mm/rev |

| K3.3 - Ductile (nodular/spheriodal) iron, pearlitic with a hardness of 220 - 260HB | Primary use | 59 m/min | 0.513 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K4.1 - Austenitic cast iron with a hardness of < 180HB | Primary use | 89 m/min | 0.513 mm/rev |

| K4.2 - Austenitic cast iron with a hardness of 180 - 240HB | Primary use | 67 m/min | 0.513 mm/rev |

| K4.3 - Austempered ductile iron with a hardness of 240 - 280HB | Primary use | 49 m/min | 0.513 mm/rev |

| K4.4 - Austempered ductile iron with a hardness of 280 - 320HB | Primary use | 42 m/min | 0.513 mm/rev |

| K4.5 - Austempered ductile iron with a hardness of 320 - 360HB | Primary use | 35 m/min | 0.513 mm/rev |

| Suitability | vc | f | |

|---|---|---|---|

| K5.1 - Vermicular, compacted graphite iron with a hardness of < 180HB | Primary use | 100 m/min | 0.513 mm/rev |

| K5.2 - Vermicular, compacted graphite iron with a hardness of 180 - 220HB | Primary use | 76 m/min | 0.513 mm/rev |

| K5.3 - Vermicular, compacted graphite iron with a hardness of 220 - 260HB | Primary use | 58 m/min | 0.513 mm/rev |