RCMT 1204MOE-FM:T8430

Turning Insert - Positive

Material ID: 7977234

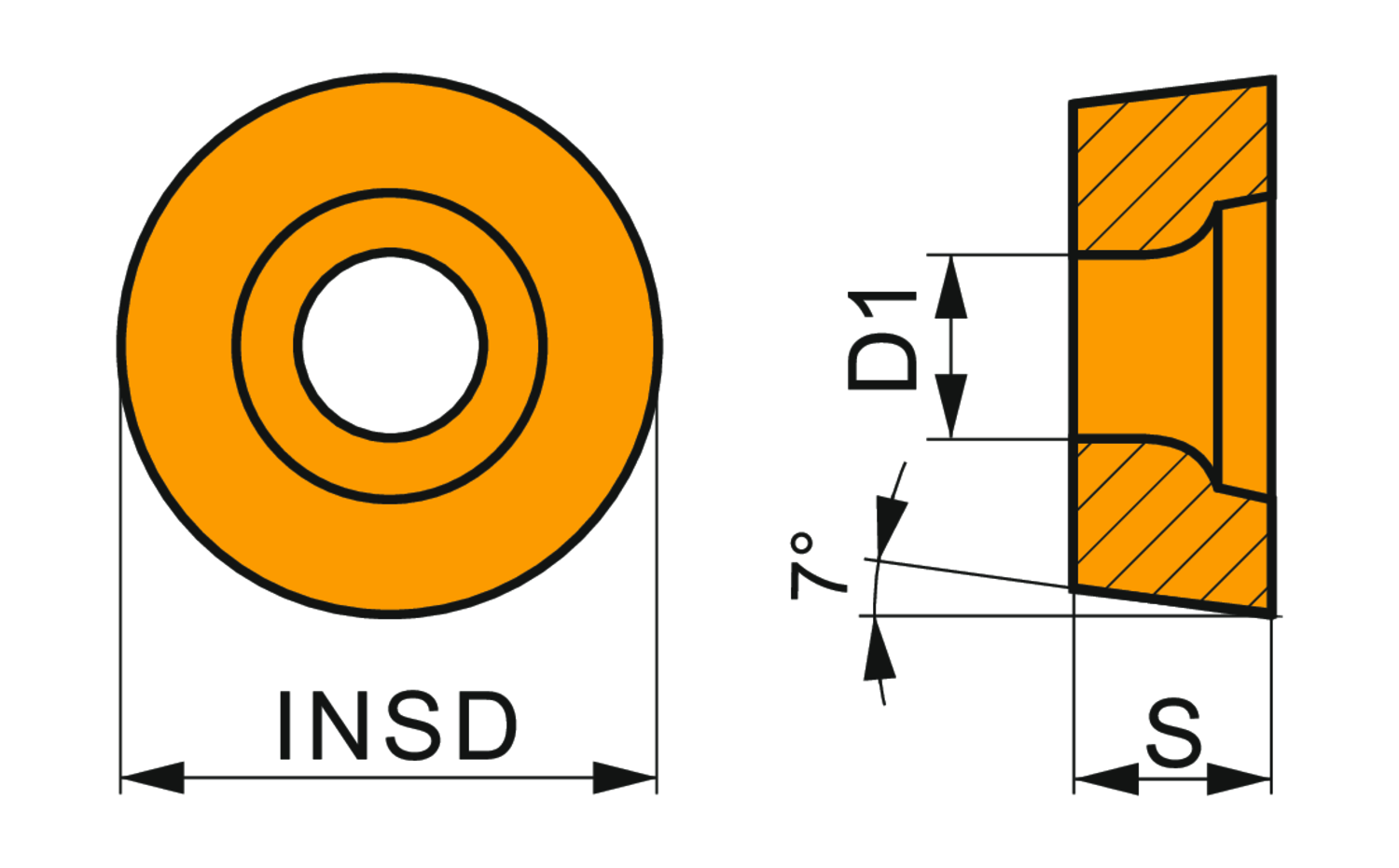

Single-sided positive turning insert, round with 7° clearance, a diameter of 12 mm, 4.76mm thick, indexing accuracy according to ISO-tolerance class-M, chip-breaker FM with rounded cutting edges, in grade T8430, a PVD coated fine grained WC-Co carbide within ISO ranges P20 -P40 and M20 -M35, for fine to medium machining of steels and stainless-steels

Product Detail

Description | Value |

|---|---|

| EAN number | 3603603818453 |

| Product number (SAP) | 80033067 |

| Ordering code ANSI | RCMT 1204MOE-FM:T8430 |

| Gross weight - grams | 6.75 |

| Insert diameter - millimeter (INSD) | 12 mm |

| Fixing hole diameter - millimeter (D1) | 4.4 mm |

| Insert thickness - millimeter (S) | 4.76 mm |

| Grade | T8430 |

| Insert Clearance Code and Angle | C 7° |

| Insert Design | RCMT |

| Insert size | 12 |

| Insert Thickness | 04 |

| Insert Type | T |

| Chipbreaker manufacturer's designation (CBMD) | FM |

| Insert shape code (SC) | R - round |

| ISO | RCMT1204MOE-FM:T8430 |

Features & benefits

- Narrow positive T-land improves the cutting edge strength allowing light feeds and enabling smooth machining with reduced heat build-up and risk of work-hardening

- 3-D chip-breaker ensures chip-breaking control at wide range of feeds and depths of cut

- Medium width chip-groove reduces the cutting resistance and vibration, hence increase machining performance

- Shallow chip-groove ensures chip breaking at wide range of cutting feeds

- Raised chip-breaker back wall height forces the chip to curl more tightly which improves the ability to chip break allowing machining of tough work-materials with lower feeds

- Highly positive geometry reduces the cutting forces and machining load significantly enabling smooth turning with minimal vibration

- WC-Co based substrate submicron grained, provides high hardness and abrasive wear resistance, resistance against comb cracks

- PVD coating, enhances thermal cracking resistance and performance in operations involving cutting temperature fluctuations

- A multi-layered PVD coating optimized for increased productivity and durability. Thick TiN coating with low compressive stress for crater wear resistance and hard AlTiN layer for flank wear resistance.

- Unique Titanium-Boron-Nitride (TiBN) top layer for build-up edge reduction and improved performance.

- New coating generation provides increased durability and performance. It is the most versatile grade for general turning and heavy roughing, even in unfavourable conditions.

Cutting Conditions

| Suitability | ap | vc | f | |

|---|---|---|---|---|

Primary use | 0.7 - 4.8 mm | 120 - 235 m/min | 0.3 - 1 mm/rev |

| Suitability | ap | vc | f | |

|---|---|---|---|---|

Primary use | 0.7 - 4.8 mm | 65 - 125 m/min | 0.33 - 0.9 mm/rev |

| Suitability | ap | vc | f | |

|---|---|---|---|---|

Possible use | 0.7 - 4.8 mm | 95 - 190 m/min | 0.3 - 1 mm/rev |

| Suitability | ap | vc | f | |

|---|---|---|---|---|

Possible use | 0.7 - 4.8 mm | 165 - 750 m/min | 0.3 - 1.2 mm/rev |