Finishing – very good surface quality - Possible use

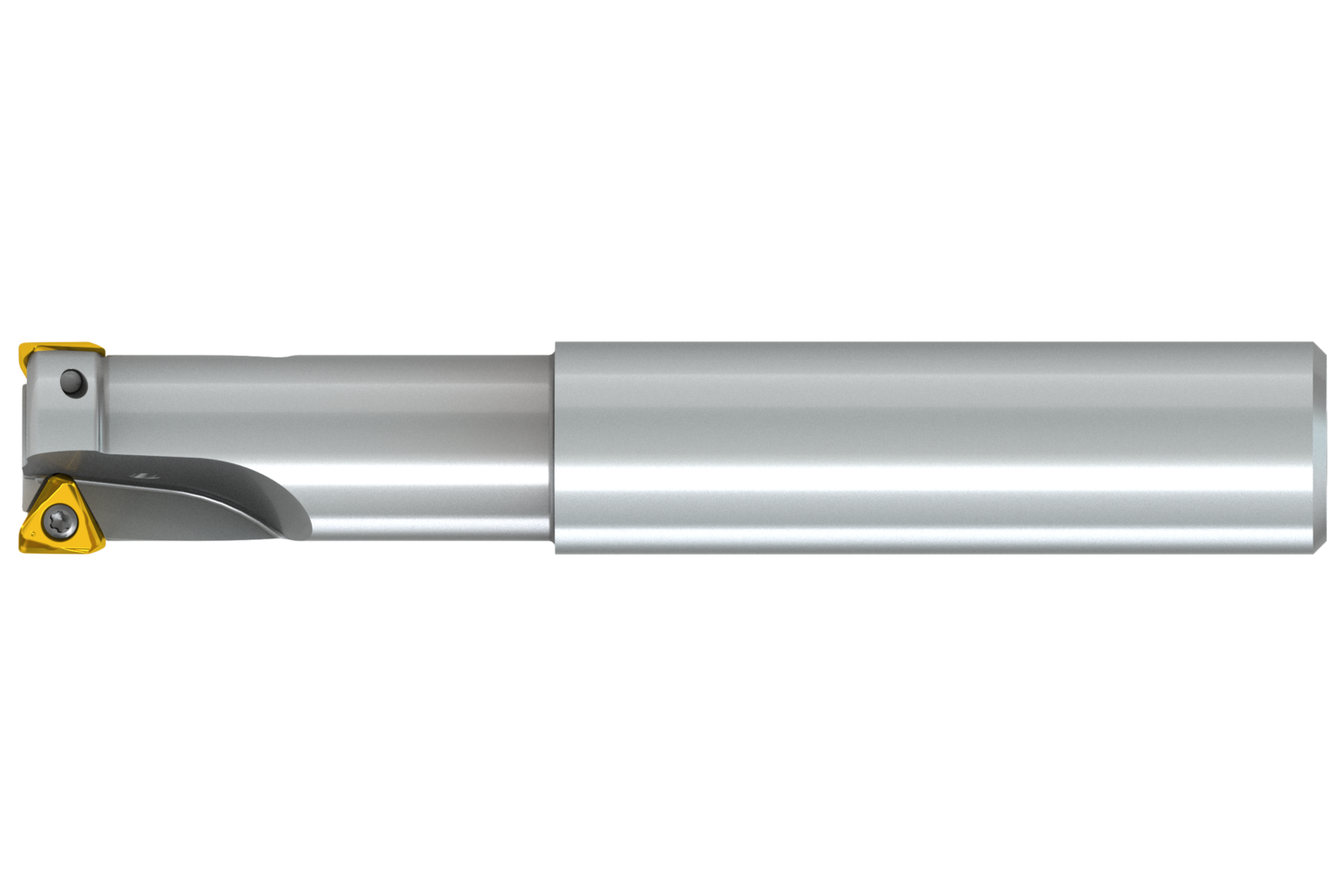

125A2R315C125-ISTN16-C

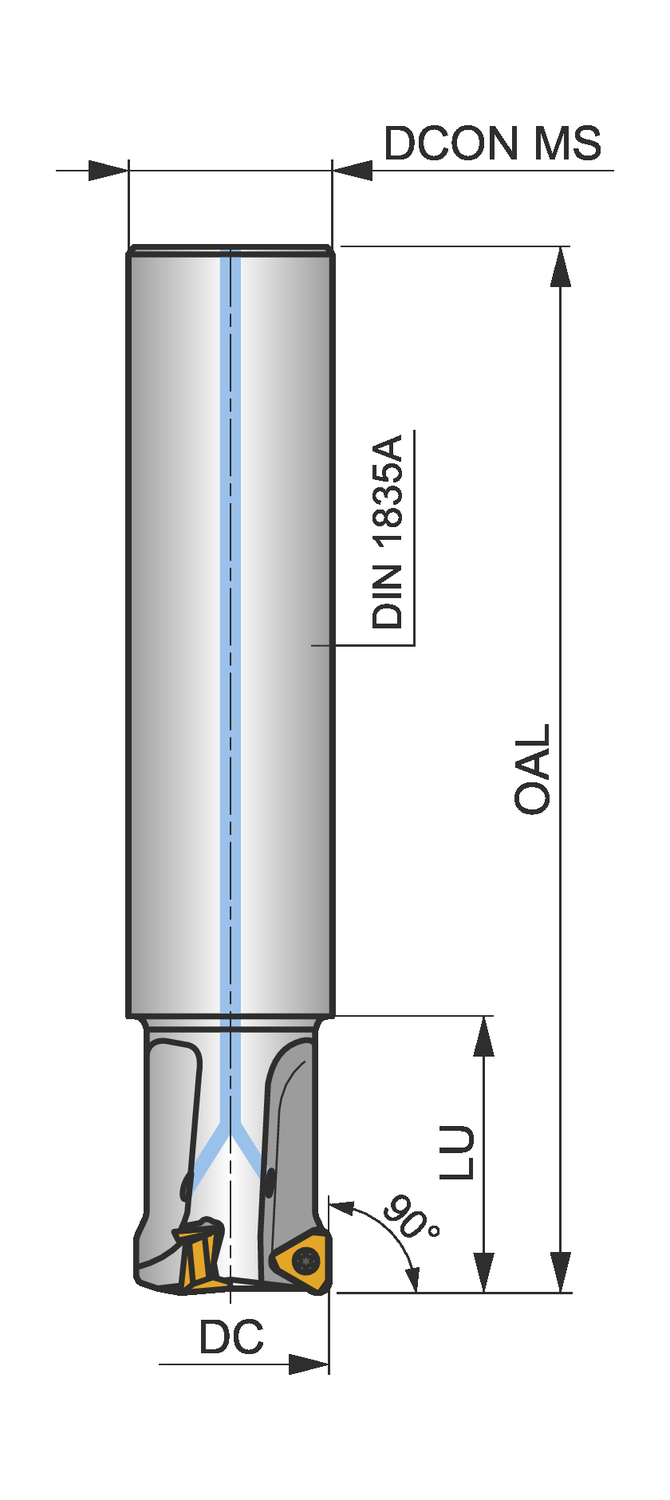

End Milling Cutter - Square Shoulder

Material ID: 8021686

Shoulder face mill with double negative geometry which utilises 2 of TNGX 1606.. double-sided inserts, cutting diameter 1.250" with 90° approach angle and parallel shank according to DIN 1835A, , through coolant for face milling, shallow shoulder milling, shallow slot milling and helical milling in pre-machined holes

Product Feature

Medium machining – good surface quality - Primary use

Suitable for unstable working conditions - Possible use

Suitable for stable working conditions - Primary use

S – Screw clamp

DIN 1835A Cylindrical Shank

Right Hand Rotation / Cutting

Product Operation

Face Milling - Primary use

Shallow Shoulder Milling - Primary use

Shallow Slot Milling - Primary use

Helical interpolation in a pre-drilled hole - Primary use

Product Detail

Description | Value |

|---|---|

| Product name | 125A2R315C125-ISTN16-C |

| Ordering code ANSI | 125A2R315C125-ISTN16-C |

| Product number (SAP) | 86037914 |

| EDP number | 8021686 |

| EAN number | 3603603843127 |

| Product Line | ECON TN |

| Cutting diameter - millimeter (DC) | 31.75 mm |

| Cutting diameter - inch (DC) | 1.25 inch |

| Cutter Design | STN16 |

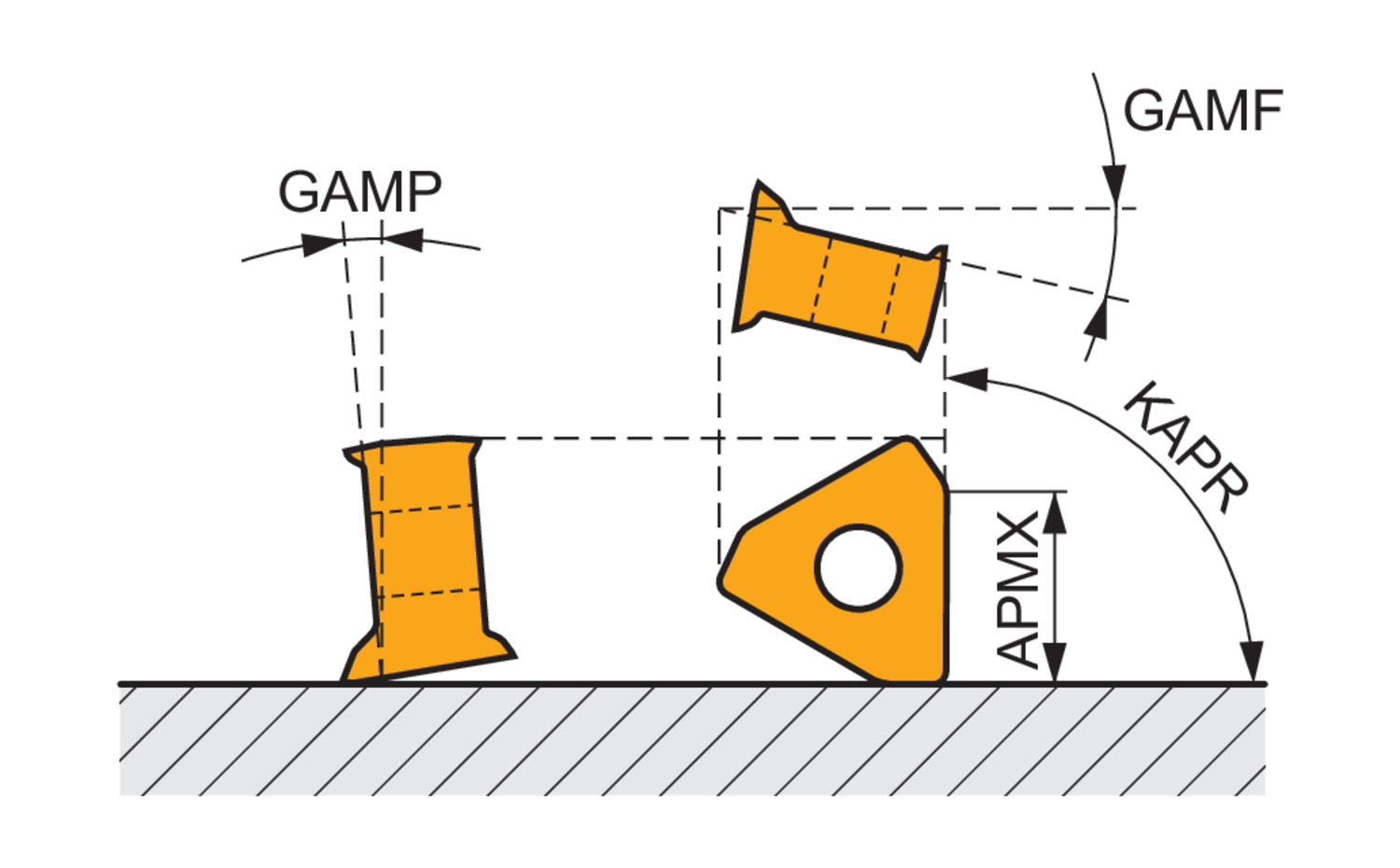

| Axial rake angle (GAMP) | -9.5 |

| Connection diameter - inch (DCON MS) | 1.26 inch |

| Connection diameter - millimeter (DCON MS) | 31.75 mm |

| Overall length - inch (OAL) | 7.677 inch |

| Overall length - millimeter (OAL) | 195 mm |

| Peripheral effective cutting edge count (ZEFP) | 2 |

| Radial rake angle (GAMF) | -16 |

| Usable Length - inch (LU) | 3.15 inch |

| Usable Length - millimeter (LU) | 80.01 mm |

| Gross weight - grams | 968.1 |

| ISO | 125A2R315C125-ISTN16-C |

| Net weight - grams | 941 |

Features & benefits

- Higher number of teeth for greater productivity, compared to original assortment.

- Internal cooling facilitates a better cooling of the cutting edges and safer and easier chip evacuation

- Precision machined pocket design for repeatability and security.

- Large and strong clamping screws for easier handling and stability.

- Manufactured from coated tool steel for better resistance against corrosion and helps to reduce friction.