DNMG 150612E-RM:T9415

Turning Insert - Negative

Main properties

Material ID: 8244277

ISO Code: DNMG 443-RM:T9415

AvailabilityIn stock

Availability in Distribution Centres

Europe Distribution Center(default): 1840

Americas Distribution Center: 0

Description

Double-sided negative turning insert, 55° rhomboid with inscribed circle diameter of 12.7mm, 6.35mm thick, 1.2mm nose radius, indexing accuracy according to ISO-tolerance class-M, chip-breaker RM with rounded cutting edges, in grade T9415, a MT-CVD coated functionally graded WC-Co carbide within ISO range P05 -P30, for medium to heavy machining of steels

Product Detail

| Description | Value |

|---|---|

| Product name | DNMG 150612E-RM:T9415 |

| Ordering code ANSI | DNMG 443-RM:T9415 |

| EAN number | 3603604014601 |

| Corner radius - millimeter (RE) | 1.2 mm |

| Cutting edge length - millimeter (L) | 15.5 mm |

| Fixing hole diameter - millimeter (D1) | 5.16 mm |

| Chipbreaker manufacturer's designation (CBMD) | RM |

| Inscribed circle diameter - millimeter (IC) | 12.7 mm |

| Insert shape code (SC) | D - rhombic 55° included angle |

| Insert thickness - millimeter (S) | 6.35 mm |

| Insert Clearance Code and Angle | N 0° |

| Insert Design | DNMG |

| Insert Geometry | Negative |

| Insert size | 15 |

| Insert Thickness | 6 |

| Insert Type | G |

| Machining Operation | Roughing |

| Grade | T9415 |

| Tool Design | DN |

| ISO | DNMG150612E-RM:T9415 |

| ANSI | DNMG443-RM:T9415 |

| Brand Name | Dormer Pramet |

| Net weight - grams | 14.729 |

| Gross weight - grams | 14.729 |

| Product number (SAP) | 80034801 |

| EDP number | 8244277 |

Related Parts

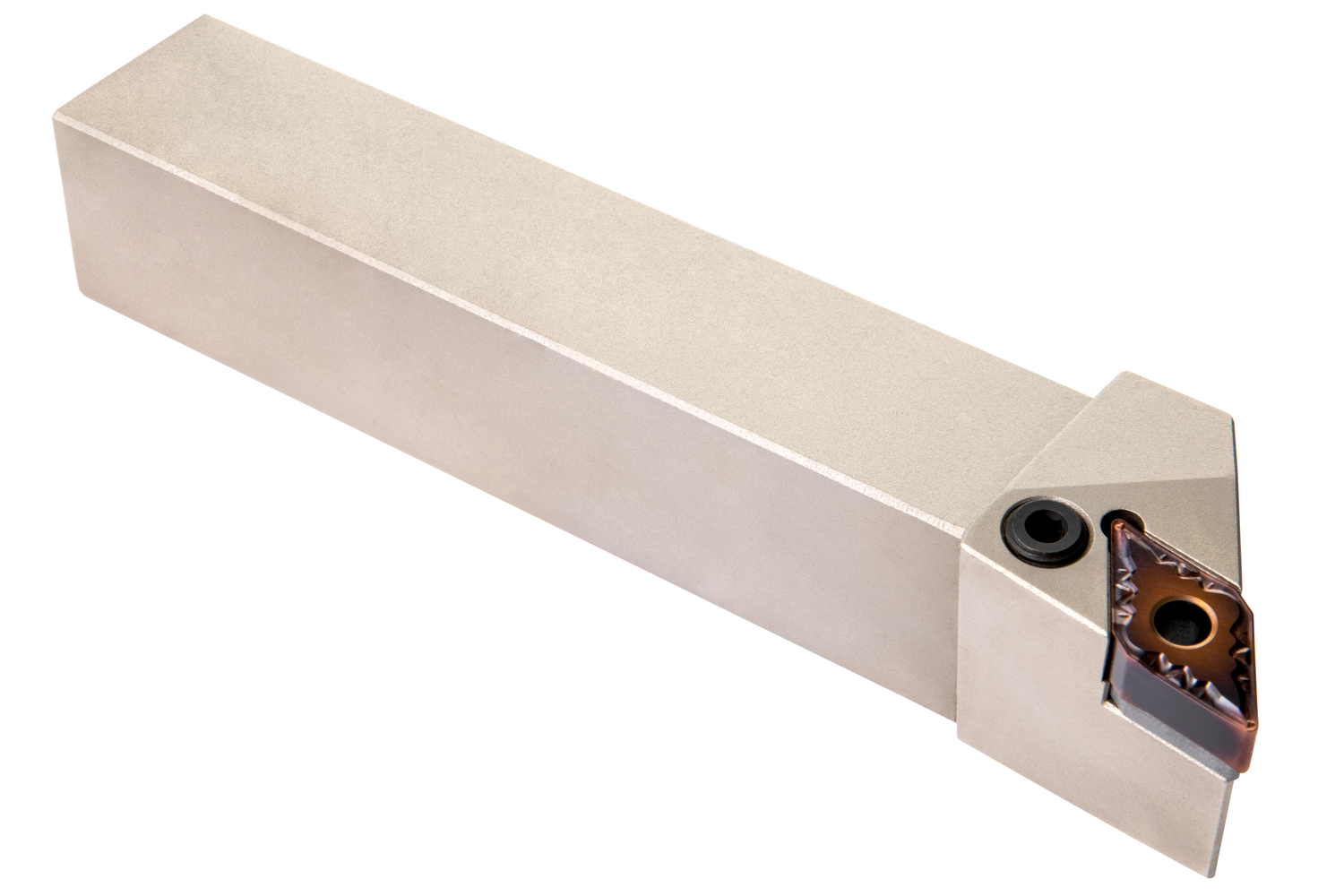

PDXN(RL) EXTTurning Toolholder ISO P

PDNN(RL) EXTTurning Toolholder ISO P

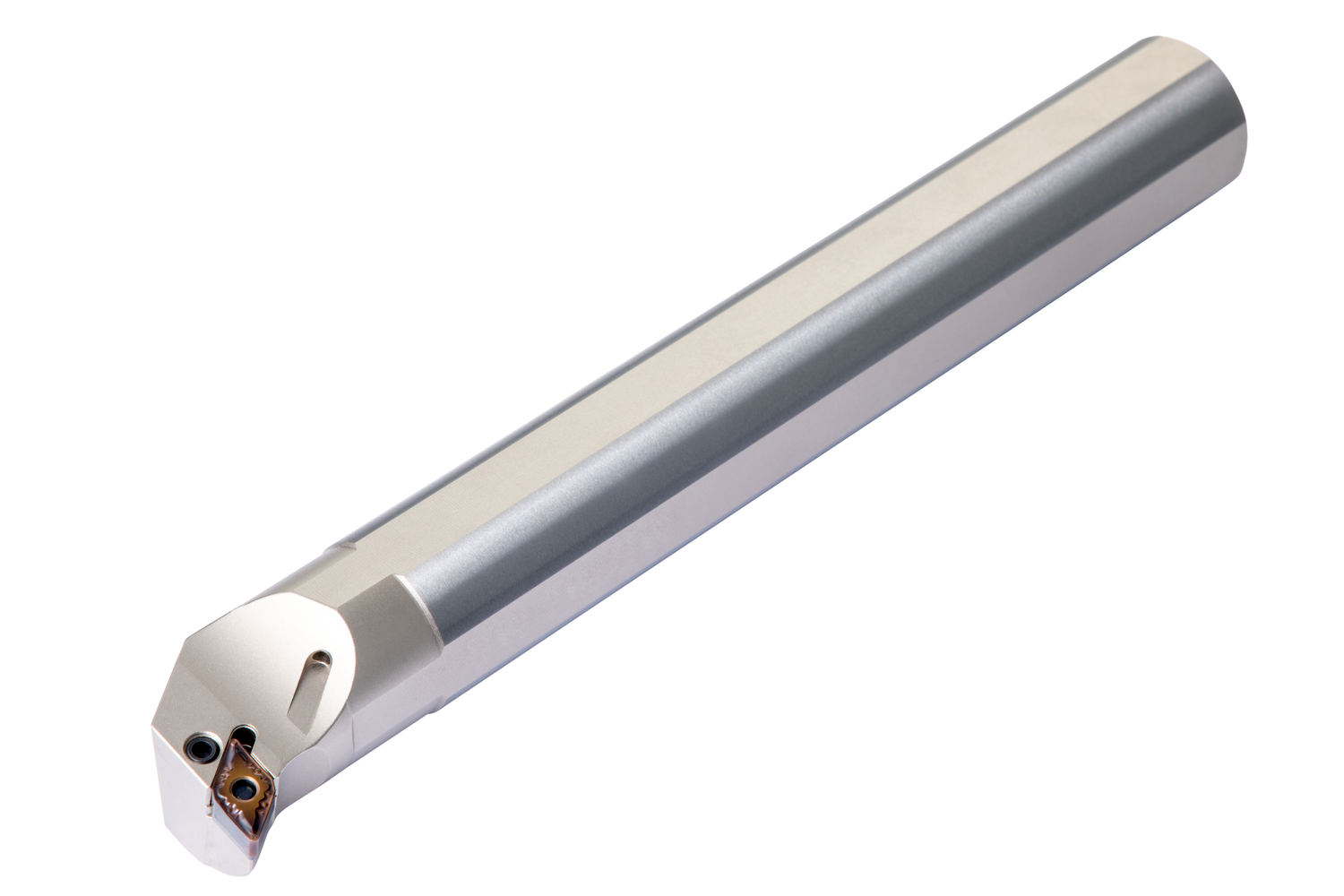

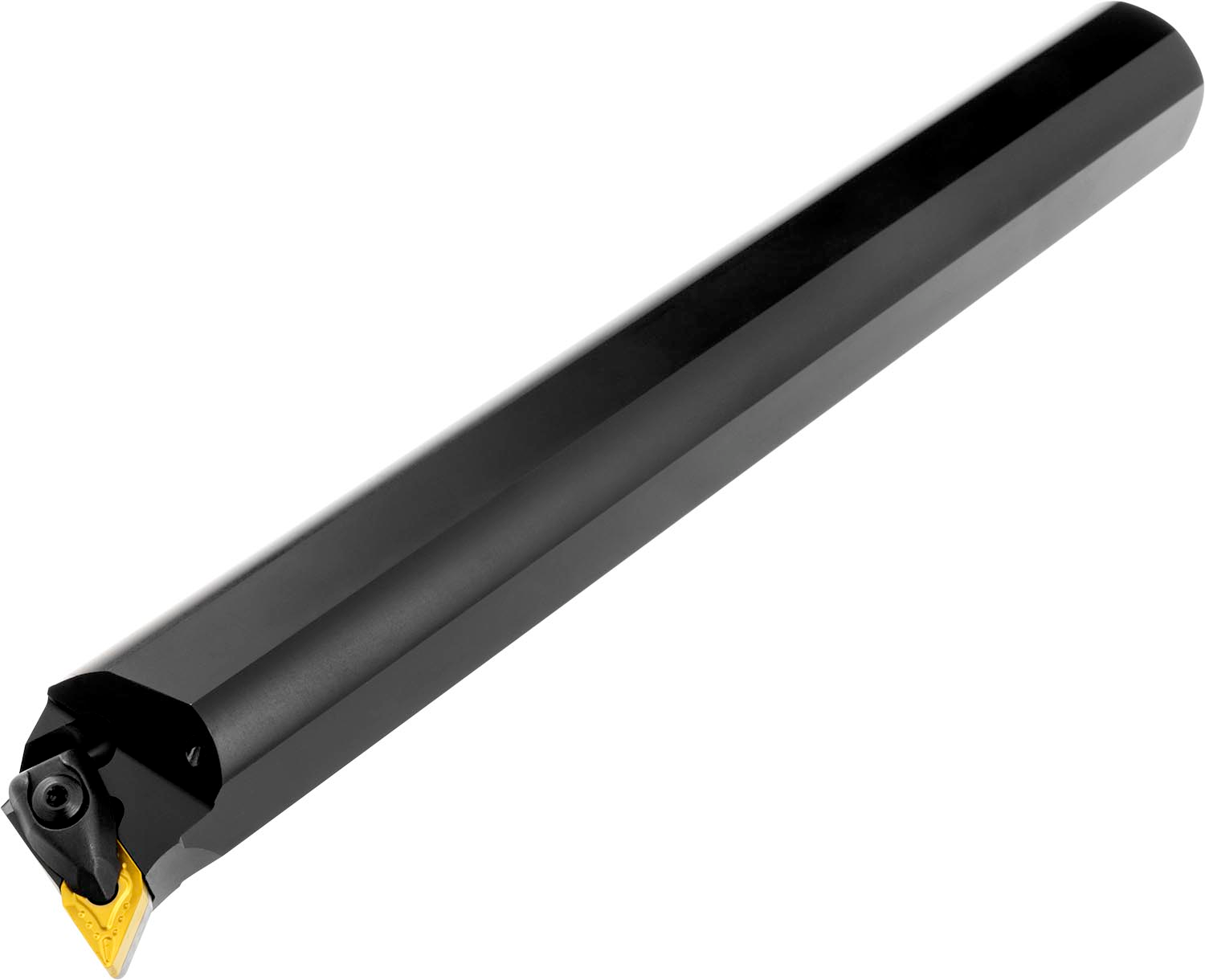

PDUN(RL) INTBoring Bar ISO P

PDJN(RL) EXTTurning Toolholder ISO P

DDJN(RL) EXTTurning Toolholder ISO D

DDUN(RL) INTBoring Bar ISO D

C.-DDNNN EXTTurning Toolholder Polygon Shank Coupling ISO D - External

C.-DDUN(RL) EXTTurning Toolholder Polygon Shank Coupling ISO D - External

C.-DDJN(RL) EXTTurning Toolholder Polygon Shank Coupling ISO D - External

Cutting Conditions

PP - Steel and cast steel (steels with alloy content ≤ 10% and a hardness of < 45HRC)

KK - Cast Iron (castings of iron and carbon alloys with > 2% carbon content)