Aluminium Chromium Nitride Coating

S26210.0XR0.5

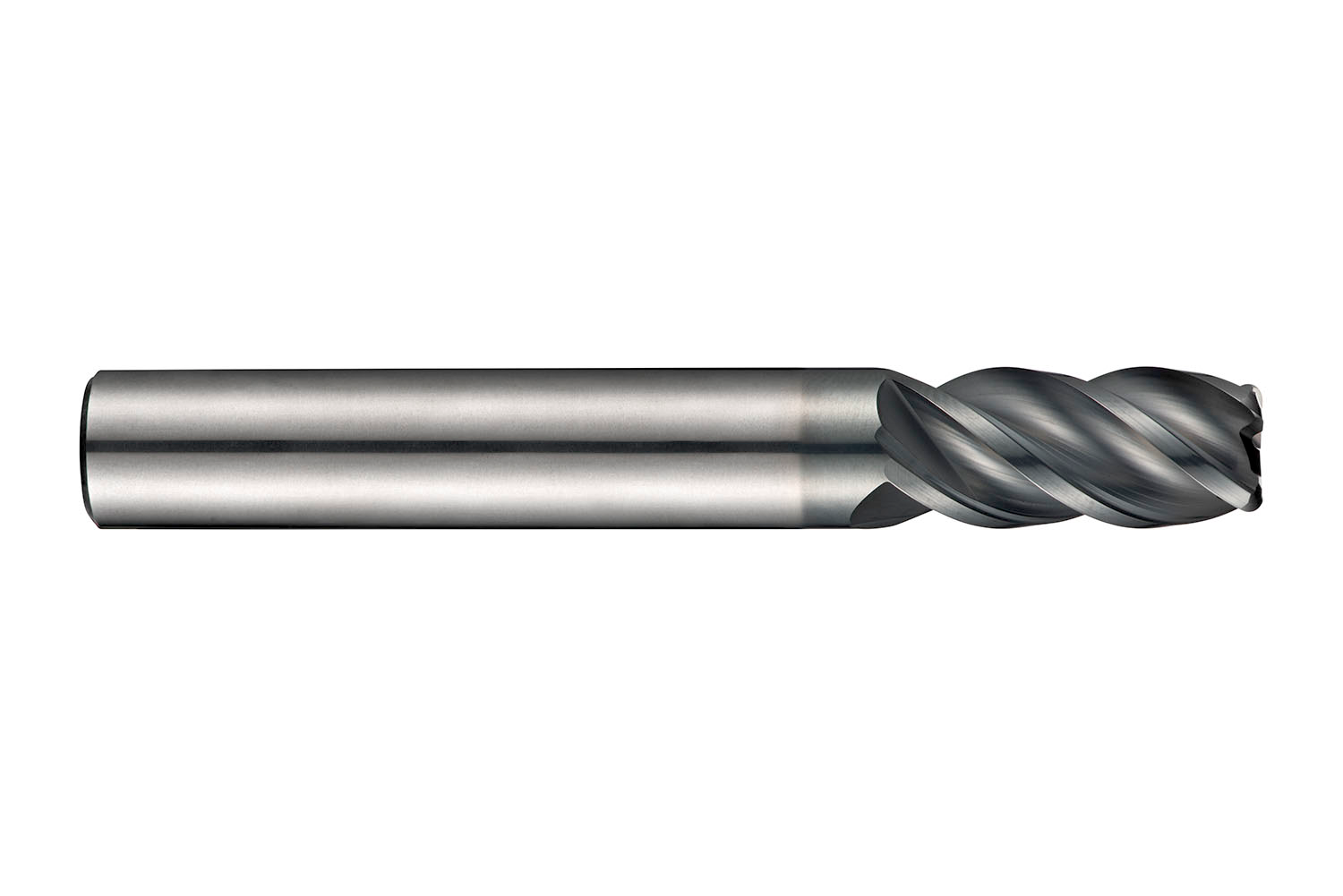

Corner Radius End Mill

Ordering number: 6706940

Short series corner radius end mill with 4 flutes, diameter 10mm with 22mm length of cut, 72mm overall length and 0.5mm corner radii, according to DORMER standard with a 10mm plain shank, solid carbide with AlCrN coating, 40° helix with differential pitch and 4° rake angle for shoulder milling, plunging, progressive plunge milling, ramping and helical milling in martensitic, austenitic and super-austenitic, Duplex or precipitation hardening stainless steel, high-temperature alloys, chilled, hardened cast-iron and hardened steel <55HRC

Product Feature

Hard Material (Solid Carbide)

General Purpose Cutter Type for Low to High Resistance Materials

Cut Length, Short

40° Helix Angle (Flute)

DIN 6535 HA Cylindrical Shank

h9 – Industry Standard Tool Tolerance Zone (based on diameter range)

Radial, Diagonal, Axial

Dormer Standards

Number of Flutes = 4 (teeth) differential pitch

Product Operation

Face Milling - Possible use

Shallow Shoulder Milling - Primary use

Deep Shoulder Milling - Possible use

Plunge Milling - Primary use

Shallow Slot Milling - Possible use

Ramping - Primary use

Progressive Plunging - Primary use

Helical Interpolation - Primary use

Trochoidal Milling - Primary use

Product Detail

Description | Value |

|---|---|

| EAN number | 7320760684894 |

| EDP number | 46706940 |

| Product name | S26210.0XR0.5 |

| Ordering code ANSI | S26210.0XR0.5 |

| Gross weight - grams | 74 |

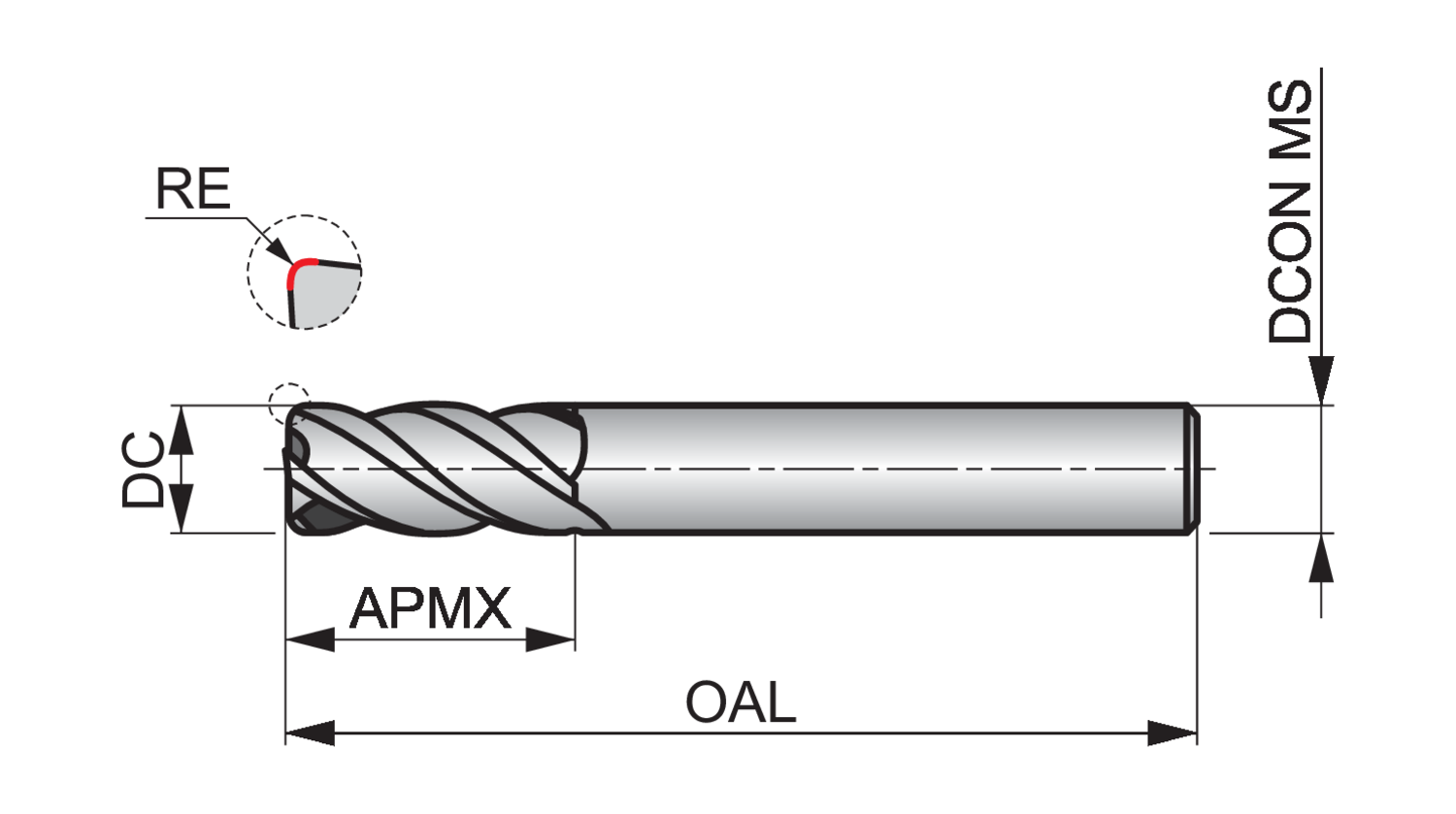

| Cutting diameter - millimeter (DC) | 10 mm |

| Corner radius - millimeter (RE) | 0.5 mm |

| Connection diameter - millimeter (DCON MS) | 10 mm |

| Depth of cut maximum - millimeter (APMX) | 22 mm |

| Overall length - millimeter (OAL) | 72 mm |

| Flute count (NOF) | 4 |

| Radial rake angle (GAMF) | 4 |

| ANSI | S26210.0XR0.5 |

| ISO | S26210.0XR0.5 |

Cutting Conditions

| Suitability | vc | f | |

|---|---|---|---|

| P4.3 - Tool steel with a hardness of 39 - 45HRC | Primary use | 318 ft/min | 0.0022 inch/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M2.3 - Stainless steel, martensitic with a hardness of 280 - 380HB | Primary use | 318 ft/min | 0.0022 inch/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M3.3 - Stainless steel, austenitic with a hardness of 260 - 300HB | Primary use | 325 ft/min | 0.0019 inch/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M4.1 - Stainless steel, austenitic-ferritic or super-austenitic with a hardness of < 300HB | Primary use | 318 ft/min | 0.0019 inch/rev |

| M4.2 - Stainless steel, precipitation hardening austenitic with a hardness of 300 - 380HB | Primary use | 272 ft/min | 0.0019 inch/rev |

| Suitability | vc | f | |

|---|---|---|---|

| S1.3 - Titanium alloys, a hardness of 280 - 360HB | Primary use | 230 ft/min | 0.0019 inch/rev |

| Suitability | vc | f | |

|---|---|---|---|

| S2.2 - High-temperature Fe-based alloys with a hardness of 200-280HB | Primary use | 184 ft/min | 0.0019 inch/rev |

| Suitability | vc | f | |

|---|---|---|---|

| S3.2 - High-temperature Ni-based alloys with a hardness of 280 - 360HB | Primary use | 131 ft/min | 0.0019 inch/rev |

| Suitability | vc | f | |

|---|---|---|---|

| S4.2 - High-temperature Co-based alloys with a hardness of 240 - 320HB | Primary use | 105 ft/min | 0.0019 inch/rev |

| Suitability | vc | f | |

|---|---|---|---|

| H1.1 - Chilled cast iron with a hardness of <440HB | Primary use | 587 ft/min | 0.0015 inch/rev |

| Suitability | vc | f | |

|---|---|---|---|

| H2.1 - Hardened cast iron with a hardness <55HRC | Primary use | 348 ft/min | 0.0012 inch/rev |

| Suitability | vc | f | |

|---|---|---|---|

| H3.1 - Hardened steel with a hardness of <51HRC | Primary use | 387 ft/min | 0.0012 inch/rev |

| H3.2 - Hardened steel with a hardness of 51 - 55HRC | Primary use | 318 ft/min | 0.0012 inch/rev |