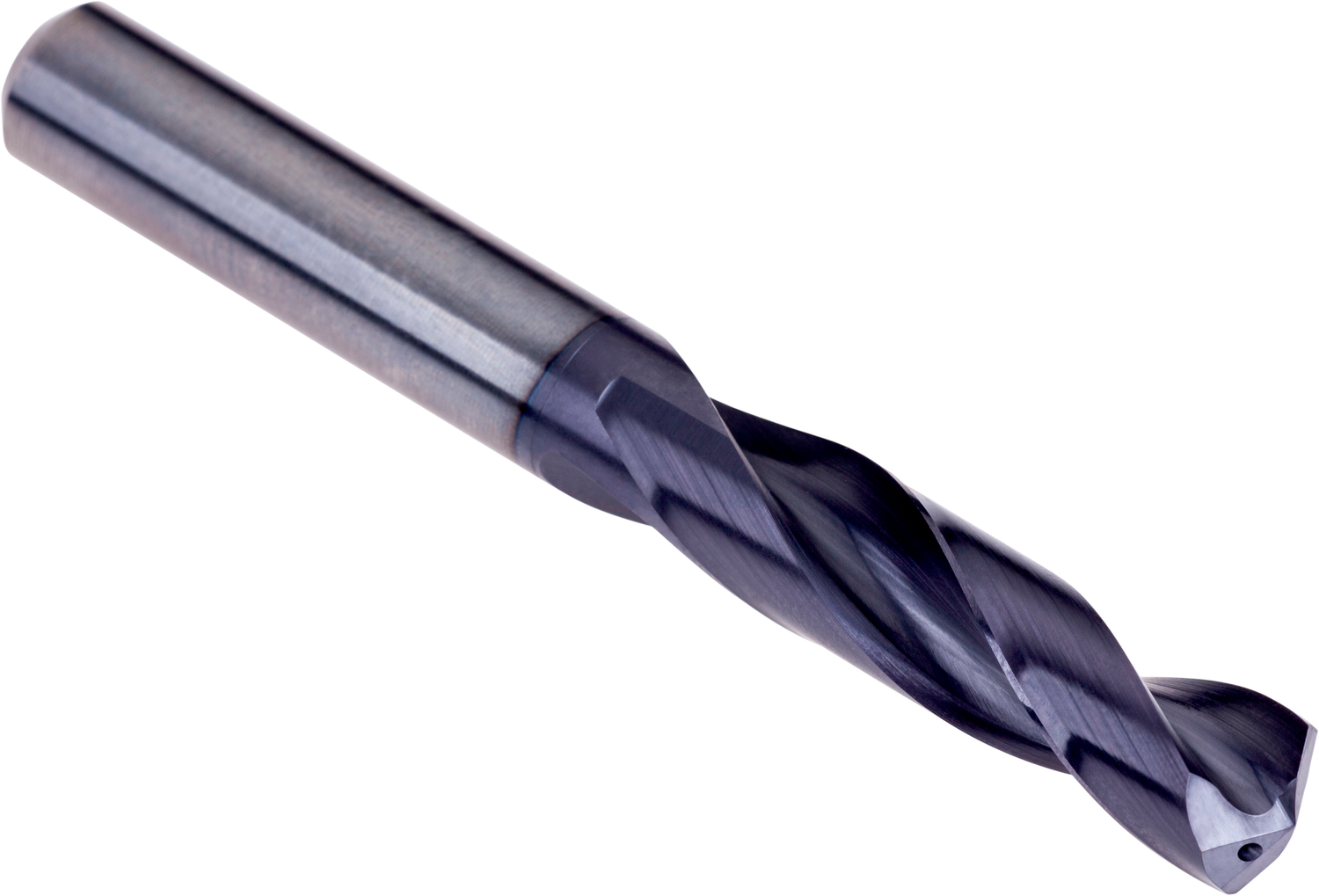

Titanium Aluminium Nitride Coating

R46710.0

Force M Drill Oil Feed 3×D

Ordering number: 7625195

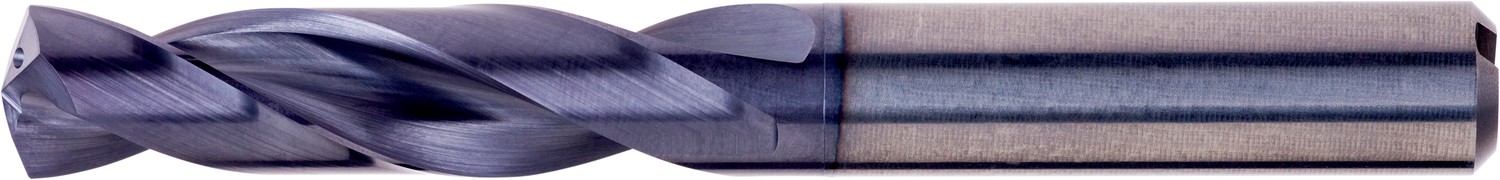

High-performance FORCE M drill with DIN 6535HA NC parallel shank, diameter 10mm with an overall length of 89mm and flute length of 47mm according to DIN 6537 K standard with 140° S-shape 4-facet split point, solid carbide with TiAlN coating, continiously thinned parallel web and through coolant holes for 3xD drilling without pecking in stainless steel and super-alloy

Product Feature

Hard Material (Solid Carbide)

DIN 6537 K

3×D Usable Tool Depth to Diameter Ratio

Drill Point 140°

DIN 6535 HA Cylindrical Shank

Continuously Thinned Web Flute Design

Through Tool Coolant

m7 – Industry Standard Tool Tolerance Zone (based on diameter range)

Product Detail

Description | Value |

|---|---|

| EAN number | 7320760837023 |

| EDP number | 7625195 |

| Product name | R46710.0 |

| Ordering code ANSI | R46710.0 |

| Product Line | FORCE M |

| Gross weight - grams | 78.5 |

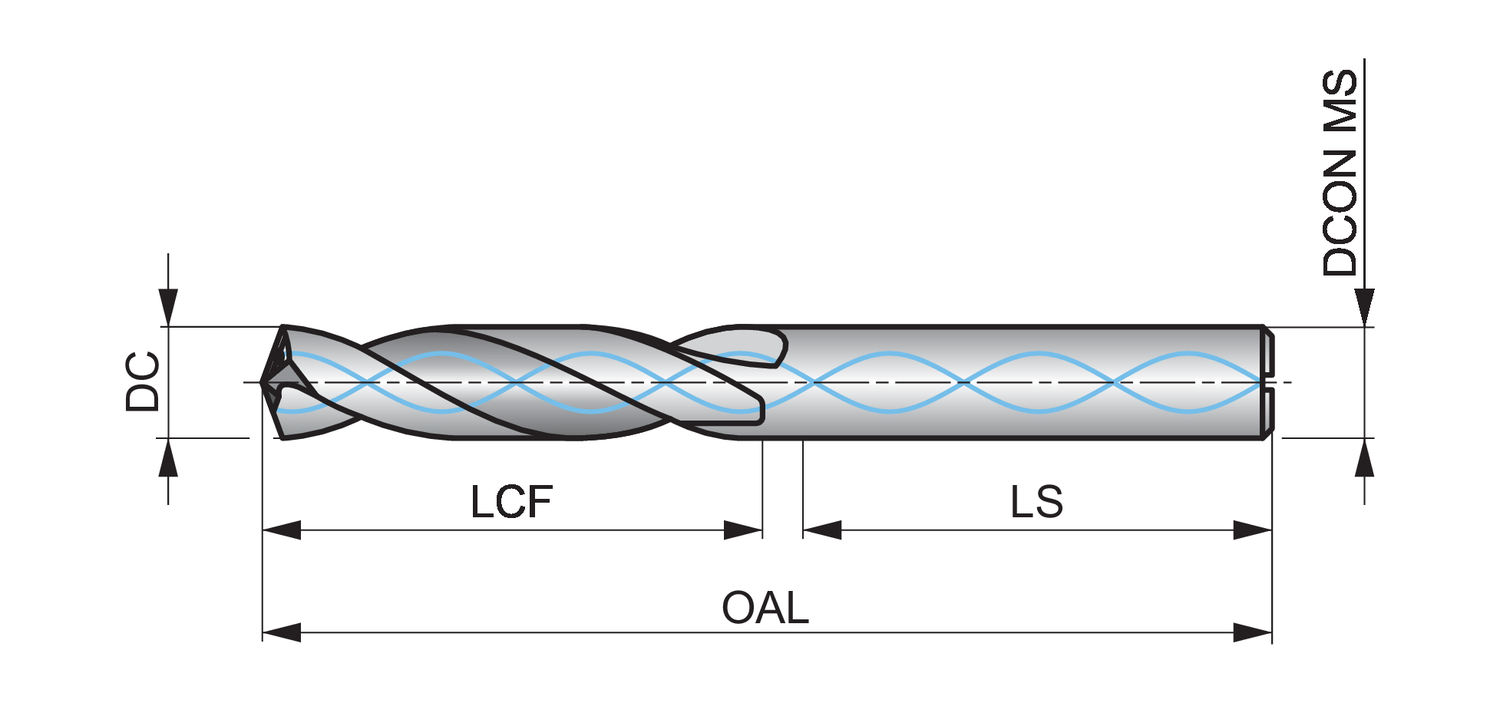

| Cutting diameter - millimeter (DC) | 10 mm |

| Cutting diameter - inch (DC) | 0.3937 inch |

| Length chip flute - millimeter (LCF) | 47 mm |

| Overall length - millimeter (OAL) | 89 mm |

| Shank length - millimeter (LS) | 40 mm |

| Connection diameter - millimeter (DCON MS) | 10 mm |

| Length chip flute - inch (LCF) | 1.8504 inch |

| ANSI | R46710.0 |

| ISO | R46710.0 |

Cutting Conditions

| Suitability | vc | f | |

|---|---|---|---|

| M1.1 - Stainless steel, ferritic with a hardness of < 160HB | Primary use | 384 ft/min | 0.0075 inch/rev |

| M1.2 - Stainless steel, ferritic with a hardness of 160 - 220HB | Primary use | 325 ft/min | 0.0075 inch/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M2.1 - Stainless steel, martensitic with a hardness of < 200HB | Primary use | 341 ft/min | 0.0075 inch/rev |

| M2.2 - Stainless steel, martensitic with a hardness of 200 - 280HB | Primary use | 279 ft/min | 0.0075 inch/rev |

| M2.3 - Stainless steel, martensitic with a hardness of 280 - 380HB | Primary use | 233 ft/min | 0.0055 inch/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M3.1 - Stainless steel, austenitic with a hardness of < 200HB | Primary use | 285 ft/min | 0.0075 inch/rev |

| M3.2 - Stainless steel, austenitic with a hardness of 200 - 260HB | Primary use | 246 ft/min | 0.0075 inch/rev |

| M3.3 - Stainless steel, austenitic with a hardness of 260 - 300HB | Primary use | 223 ft/min | 0.0065 inch/rev |

| Suitability | vc | f | |

|---|---|---|---|

| M4.1 - Stainless steel, austenitic-ferritic or super-austenitic with a hardness of < 300HB | Primary use | 197 ft/min | 0.0065 inch/rev |

| M4.2 - Stainless steel, precipitation hardening austenitic with a hardness of 300 - 380HB | Primary use | 171 ft/min | 0.0055 inch/rev |

| Suitability | vc | f | |

|---|---|---|---|

| S1.1 - Titanium or titanium alloys, with a hardness of <200HB | Primary use | 180 ft/min | 0.0098 inch/rev |

| S1.2 - Titanium alloys, with a hardness of 200 - 280HB | Primary use | 148 ft/min | 0.0098 inch/rev |

| S1.3 - Titanium alloys, a hardness of 280 - 360HB | Primary use | 131 ft/min | 0.0067 inch/rev |

| Suitability | vc | f | |

|---|---|---|---|

| S2.1 - High-temperature Fe-based alloys with a hardness of <200HB | Possible use | 197 ft/min | 0.0067 inch/rev |

| S2.2 - High-temperature Fe-based alloys with a hardness of 200-280HB | Possible use | 184 ft/min | 0.0067 inch/rev |

| Suitability | vc | f | |

|---|---|---|---|

| S3.1 - High-temperature Ni-based alloys with a hardness of <280HB | Possible use | 148 ft/min | 0.0067 inch/rev |

| S3.2 - High-temperature Ni-based alloys with a hardness of 280 - 360HB | Possible use | 131 ft/min | 0.0067 inch/rev |

| Suitability | vc | f | |

|---|---|---|---|

| S4.1 - High-temperature Co-based alloys with a hardness of <240HB | Possible use | 115 ft/min | 0.0067 inch/rev |

| S4.2 - High-temperature Co-based alloys with a hardness of 240 - 320HB | Possible use | 105 ft/min | 0.0067 inch/rev |